Present and future of palletizing

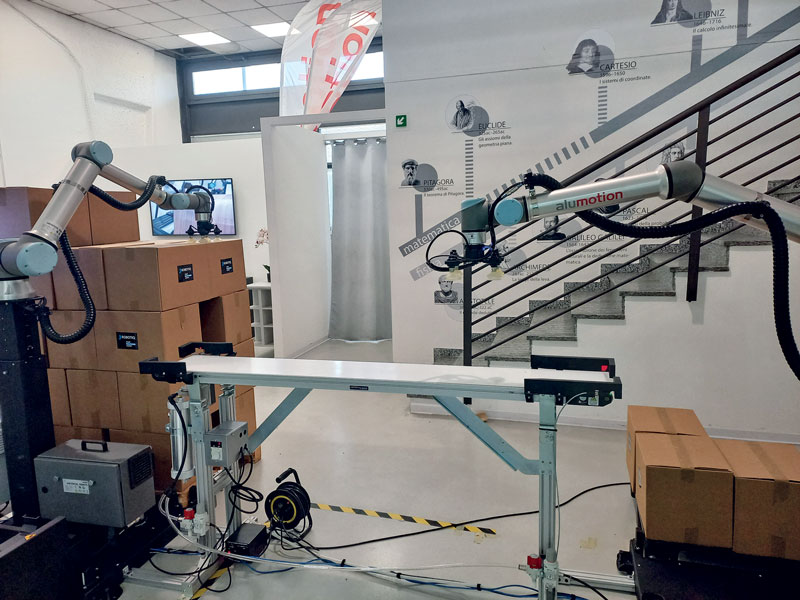

The “Cobot Palletizing Day” is the event organised by Alumotion at its Competence Center in Cernusco sul Naviglio, dedicated to collaborative robotics solutions for palletizing. It was a day of reflection, but above all an opportunity to see live the solutions of Alumotion and its partners dedicated to the end of the line.

During the “Cobot Palletizing Day”, topics discussed included collaborative robotics in palletizing, case studies, the future of the sector and the changes and, above all, the benefits which collaborative robots will bring. Held at the Alumotion Competence Center, the event was an opportunity to see the proposed solutions at work, so as to fully understand what added value they can bring to different companies. In recent years, collaborative robotics has increasingly become part of the everyday life of companies, optimising production and facilitating the work of human operators. The day opened with a round table entitled “Cobots, AMR & logistics: from end-of-line to storage”, which was attended by several high-level speakers. These included: Fabio Facchinetti, COO of Alumotion; Gloria Sormani, Country Manager for Italy of Universal Robots; the Robotiq team with the valuable presence of the CEO and founder, Samuel Bouchard; Gianmaria Peruzzi, Technical Manager, MADE Competence Center.

A cobotic round table

Of course, the pivotal question of the whole round table was: why use a collaborative robot for palletising? The answer agreed upon by all the speakers was that cobots bring with them a very high level of flexibility: a non-fixed line is more flexible in absorbing changes in production requirements, in handling parts of different shapes compared to those for which it was designed, or in dealing with completely different tasks, something which a fixed line cannot do. And not only that: new technologies can be a strong stimulus for employees, who can see them as a new challenge to improve their skills, which in turn helps the company itself to improve. Of course, robots should not be seen as a replacement for human operators, but as a support for them. It is impossible not to mention Covid-19: the pandemic has changed many things, for example it has greatly accelerated the digitisation of businesses. Although, as mentioned during the round table, many SMEs are not yet able to measure the figures of this change, and especially the long-term benefits. The transition, however, is unstoppable, even if there are some obstacles to overcome. One of these, for instance, is the lack of appropriate skills for Industry 4.0: many, and in any case not everyone, can program robots, but this is not enough. Another challenge that has been mentioned is demographics: in the Western world, the population is getting older and older, and generational turnover is not guaranteed. In addition, the advanced age of workers is likely to increase the number of errors during work, not allowing them to perform heavier tasks. This is where cobots can provide invaluable help: the human-robot combination can enable more precise and safer work, which is particularly beneficial for SMEs, which cannot afford too many mistakes and at the same time require high flexibility.

One of the main concerns of companies considering the integration of a robot into production is, quite legitimately, the ROI, that is, the time within which the investment will pay for itself. With cobots the index is often less than 12 months (and can be even faster thanks to state incentives for Transition 4.0); but to achieve this goal it is necessary to first identify the operations which are easiest to automate, so that the robot can be integrated without difficulty and become a truly effective agent of innovation and production: the help of expert integrators, in this sense, is fundamental and can make the difference between a mistaken investment and one that can, instead, quickly pay for itself. As the speakers pointed out, unfortunately many SMEs are still skeptical towards this type of technology: many have no intention of investing in it or do so superficially, installing robots as foreign bodies in the production flow, in this case at the end of the line. But technology is moving too fast, and it is necessary to follow the flow of innovation with targeted investments so that companies’ logistics can be truly modernised.

Applications and real solutions

After the round table, it was the turn of some companies which showed real application cases, where collaborative robotics supports logistics: IDEA, N.S. Sistemi and Shili Tech. These three companies showed, through videos, how automated and collaborative systems can be easily integrated into the workflow, bringing several advantages. For example, they can lift heavy boxes of fruit and vegetables, preserving the health of operators; or they can handle small objects, reducing the risk of human error. All this would also not be possible without artificial intelligence algorithms and vision systems: already very accurate today, they are expected to become increasingly complex, and in the next five years a major technological leap forward is expected. Finally, after the lunch break, it was time for the live demos. It was possible to see the Robotiq Palletizing Solution plug&play palletizing system at work, to discover the potential of the weight compensation devices developed by Cobot Lift (which increase the payload of the UR10 robotic arm by Universal Robots up to 45 kg) and to follow the Robotize GoPal AMRs transporting pallets from one workstation to another, in complete autonomy, just as can be done in any logistics. But there was more: it was also possible to see in action the Robotiq Screwdriving Solution screw tightening application and the innovative Sidebot by Wyzo, the delta robot which combines the safety and versatility of collaborative robots with the speed of industrial models, capable of achieving up to 90 cycles/min. To conclude, it was a “technological day” full of interesting suggestions for the future of logistics and palletising, together with practical examples demonstrating the concreteness of what was discussed.