The challenge of the future is presence on the territory

Since its foundation, Samac has worked to keep up with the most innovative technology. Even before the explosion of Industry 4.0, its machines were already interconnected; now it is at the forefront in the production of electric motors, a sector that is becoming increasingly important in the automotive world. Challenges, however, never stop: Samac wants to be even closer to its customers, which is why it will open its new production facility in China at the beginning of 2021.

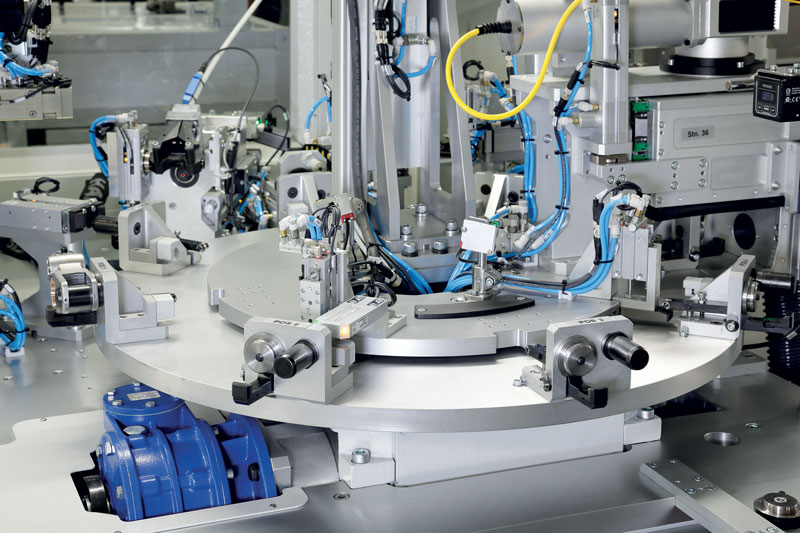

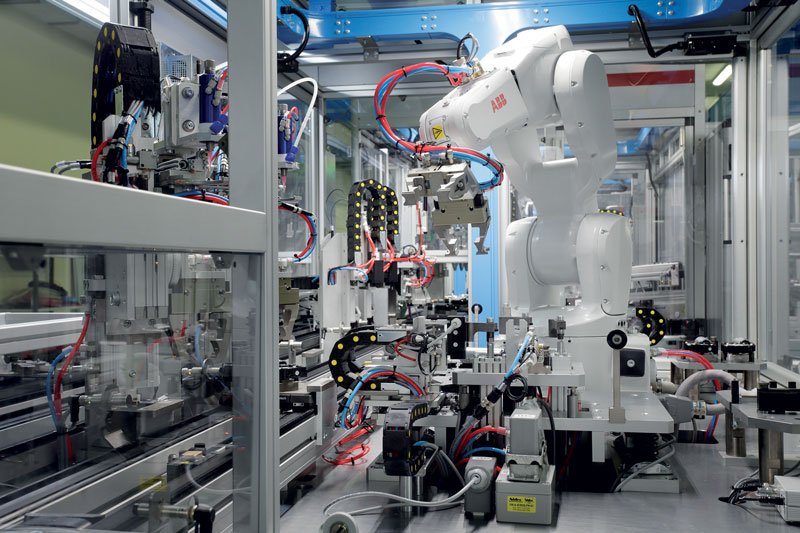

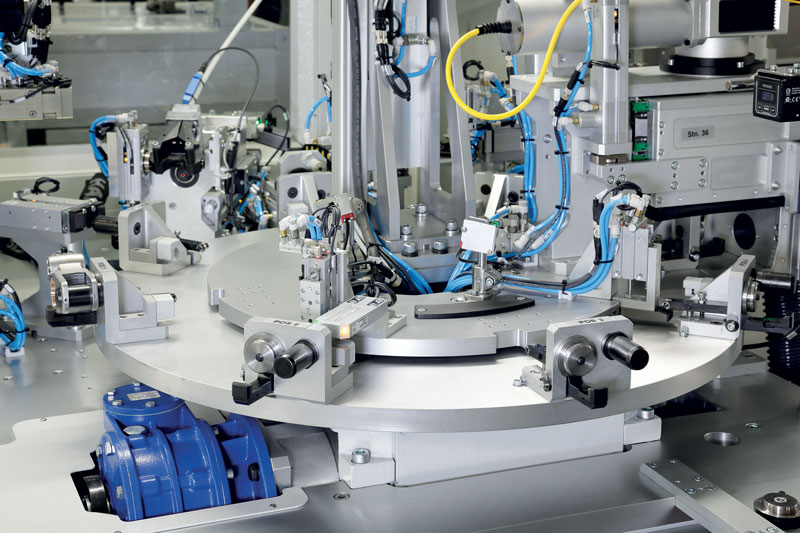

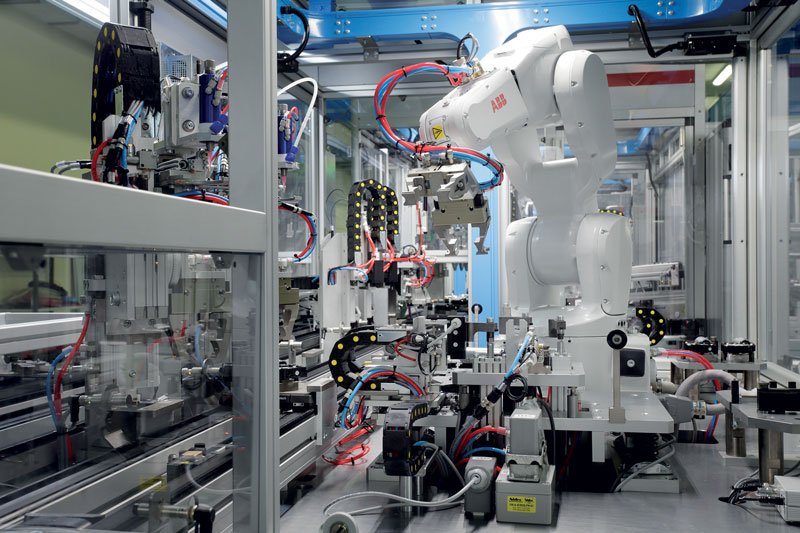

Samac was founded almost half a century ago, in 1975, in an area of Lombardy with a strong industrial vocation; the company designs, builds and installs customised machines and plants. The aim of these plants is to automate the assembly and testing processes of various products, including mechanical, electromechanical and hydromechanical components. The plants built by Samac are like “tailor-made clothes”, designed on the basis of the specifications and particular needs of each customer. The company is constantly abreast of technological innovations, sometimes arriving before their actual success. Indeed, the company developed 4.0 ready plants well before this became a topic of general interest, working on the creation of open systems that made it possible to install lines with a technologically cutting-edge and well-established factory interconnection.

It is not by chance that Samac considers the software aspect of the systems to be a predominant part of its activities, and many resources and efforts are employed in the research and development department, where the objective is to implement new features and new methods to speed up data acquisition. The aim is to continuously improve the user experience, for example through continuous graphical updates of the HMI and supervisor. But that is not all: it is also essential to constantly implement the range of tools to increase the use of information, through external apps, devices such as smartphones and tablets, wearable devices such as smartwatches and smart glasses for maintenance activities, which enable a reduction in the distance between the technician at Samac and the personnel present at that moment on the plant.

Another digital innovation process which Samac is focusing on is cloud computing and fog computing. While on the one hand, by exploiting the benefits of the cloud, it is possible to share less sensitive production data, sensors, alarms, critical thresholds and all the information that does not need to be processed in real time, with appropriate management of the hardware and software infrastructure, fog computing, thanks to its greater physical proximity to the production environment, enables a much higher performance in response capability. All this translates into shorter response times in increasingly technologically advanced plants.

The installations made by Samac aim to automate the assembly and testing processes of various products.

The systems built by Samac are like ‘tailor-made clothes’, designed according to the specifications and specific needs of each customer.

Maintenance 4.0 and the surgical mask plant

Over the years, Samac has taken many steps forward in the field of preventive and predictive maintenance linked to Industry 4.0, developing electrical and software solutions capable of monitoring individual elements. Indeed, on the plants there is constant monitoring of consumption, especially air and electricity, which is an important aspect from a sustainability standpoint which Samac is particularly concerned about. The goal of environmental sustainability permeates every aspect of the company’s business, both in its daily operations and on the plants it designs.

In 2020, the company did not stop: thanks to the tools Samac had already put in place and the partnerships it had previously established, maintenance operations never stopped, providing continuity for customers. Thanks to digital innovation, Samac was able to work well in spite of the situation; much was done remotely, of course, but the support of local partners was valuable, enabling activities to continue and the various lines to be installed on time, as agreed with the customers.

2020 has certainly demanded more flexibility from companies like Samac, who had to reinvent themselves on the various platforms to carry out work in a different way. In a professional environment where face-to-face contact with the customer is fundamental, carrying out a project, almost always a prototype, via digital platforms obviously required extra skills, and Samac’s staff managed to adapt quickly to the new context, guaranteeing the usual quality of the service provided. Also in terms of turnover, it managed to cope with the heavy worldwide crisis caused by the health emergency, closing 2020 with a turnover which will be slightly higher than in 2019.

In order to make its contribution to the fight against Covid-19, Samac has also set up a plant for the production of surgical masks, capable of producing around 60-80 masks per minute. Thanks to the good quality and certified materials, this product meets type IIR performance requirements according to the UNI 14683 regulation, certifying a bacterial filtration efficiency of over 99% and splash resistance.

The challenge of electric mobility

The aspect of eco-sustainability, therefore, is fundamental for Samac, also with regard to its market choices: indeed, it is facing the challenge of electric and hybrid mobility. Over the years, a strong know-how regarding electric motors has been developed and today Samac’s objective is to establish itself as a solution partner for its customers, going as far as to create a very close partnership with the customer’s various teams, not only those in process engineering, but often also with those in product engineering.

As regards the automotive sector, Samac specializes in creating solutions for both primary motors, that is, electric drives, and secondary motors, such as those which move, for instance, roofs and seats; it is also working on motors combined with pumps, which enable a switch from the classic mechanical water/oil pump to a fully electric one. Over the years, it has developed particular skills in various processes, starting from functional testing, passive and electrical testing, to dispensing of polyurethane and two-component glues, to welding, right up to vision systems and dimensional controls, which in the automotive sector require high levels of redundancy. In terms of mechanical couplings too, Samac has manufactured its presses and the related software with supervisor interface in-house, so as to be more independent from suppliers and to provide the most customized solution possible.

Samac, thanks to the skills it has developed, its technology and the experience of its various customers which have enabled it to grow over the years, wants to be one of the leading players in this change.

The installations made by Samac aim to automate the assembly and testing processes of various products.

The systems built by Samac are like ‘tailor-made clothes’, designed according to the specifications and specific needs of each customer.

The new production facility in China

The other great challenge undertaken by Samac concerns the new production site opened at the beginning of 2021 in China. A path which began as early as 2015, with an initial initiative to launch a joint venture together with a local partner and the registration of the brand, leading in 2019 to the creation of a representative office in the city of Ningbo, which gave concrete form to the project. The need to open a production site in China arose because many customers already served in Europe have production sites in China, and were asking Samac to be close to them. This way the company can be more responsive to their requests. The investment plan is spread over five years, and the identified location is in a technologically advanced area, where important multinational companies, both clients and potential clients, are already based: Samac wants to create a commercial network parallel to that of the Italian headquarters. Samac also wants to create a close synergy with China: three Chinese operators will be trained in Italy, and Italian personnel will be transferred to China. Besides, there is a trustworthy person on site with whom Samac has been collaborating for a long time for the Chinese market: the partner who has already taken care of the opening of the representative office is an Italian citizen who, however, has been living in China for years, and can therefore be an effective interface between local companies and Samac, facilitating interaction and trust between the parties.

The Chinese and Far Eastern markets are important to Samac, since the local automotive and electro-mobility sectors are currently undergoing a strong expansion phase. The company is also planning further expansion into East Asia, and is turning its attention to the Japanese market, carrying on negotiations to create a joint venture with a Japanese-based company, a partner able to provide service and maintenance. But the future is not only in the Far East: in the United States of America Samac has several installations underway and, as well as an existing sales agency, it is strengthening its presence by signing a partnership with a local operator, in order to overcome any problems in terms of mobility which might result from the tightening of restrictions caused by the pandemic. At the moment the focus is on China, but Samac does not rule out the possibility of opening a plant on the American continent in the future. The intention to transform Samac into a major player in automation with an international network is strong and the teams involved are working with great dedication to ensure that the ambitious projects in the field will lead to the desired results.