Quick in name and in fact

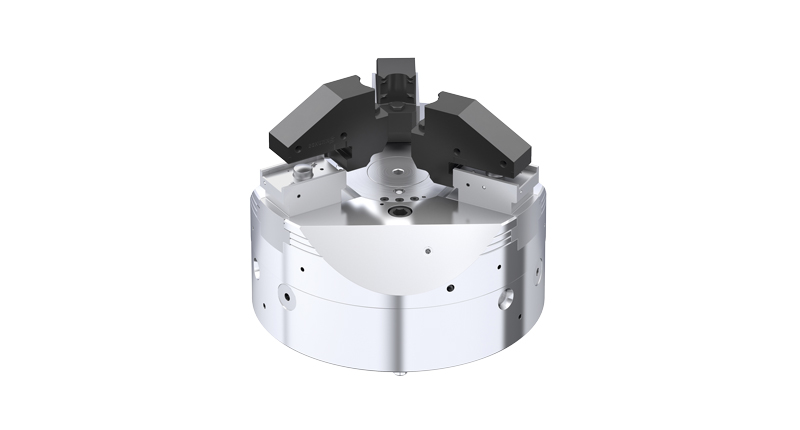

SCHUNK presents its new RAPIDO series clamp changer, which allows a spindle to be retooled in just one minute. This system provides an accuracy of <0.02 mm and is optionally equipped with an RFID chip, QR code or individual labelling.

It takes a maximum of 60 seconds until a conventional 3-jaw chuck with SCHUNK’s RAPIDO (that means quick in Italian) clamping inserts is retooled. For granting such a speedy jaw change, the RAPIDO clamping inserts must be put onto the base or intermediate jaws and moved backwards until they snap in. The exchange can be done manually or in case of lathe chucks with integrated base jaws, it can be done fully automatic with a robot. A locking mechanism always ensures safe hold of the snapped-in clamping inserts, even if they are not clamped. The system can be used, no matter if the spindle is horizontally and vertically positioned. Due to the high-precision quick-change interface, the SCHUNK RAPIDO achieves an appropriate repeat accuracy of <0.02 mm for many types of finish machining. The quick-change system can be used for I.D. and O.D. clamping. In order to ensure the necessary flexibility, SCHUNK has launched a concept of jaw blanks consisting of soft clamping inserts of different heights. What is more: due to this concept, clamping inserts with claw jaw contour, application-specific, or weight-reduced versions can be manufactured as a modified standard version within a very short time, or the users can machine them by themselves. On request, the RAPIDO clamping inserts can be individually equipped with an RFID chip, QR code, or an individual labelling. Other variants are available as a special design.

Fully incorporated or as a retrofit kit

RAPIDO from SCHUNK is available in two versions. The first is to be completely integrated into the chuck body. In this case the chuck will be equipped with the basic RAPIDO jaws before being delivered to the customer. The jaw change in this version can be performed either manually or automatically by robot. The second version consists of installing the basic RAPIDO interface in an existing chuck, placing an intermediate jaw on the existing basic jaws and replacing the respective gripper jaws. In this version, the quick replacement of the clamps is done by means of a pin positioned laterally on the base jaw. In the latter version, if the intermediate base jaw is removed, it is possible to continue to use the existing clamps with conventional inch or metric gear interfaces.