Modular gripping systems are more universal

SCHUNK further expands the idea of simply equipping cobots with its Plug & Work portfolio onto lightweight robots from Doosan Robotics and Techman Robot, manufacturers that have come more and more into the focus of users worldwide. With the introduction of the Plug & Work portfolio, SCHUNK responds on this development but also adapts its standard product line of proven components used in industrial applications attached to different cobots.

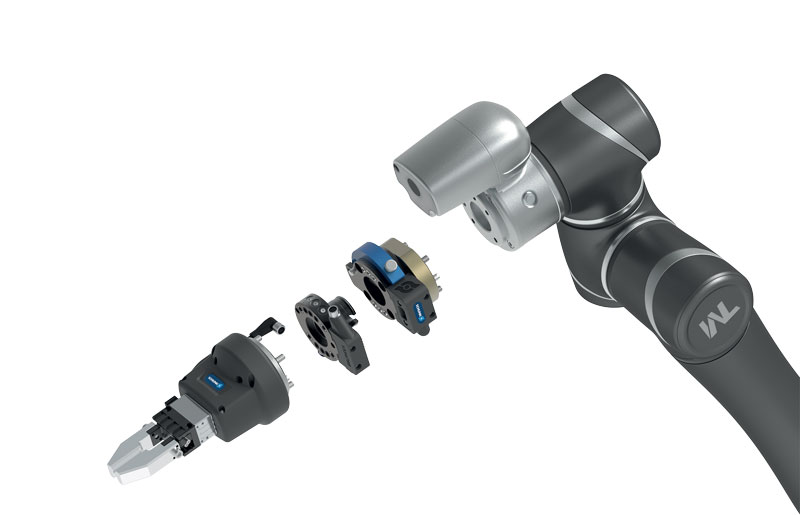

The customized Plug & Work portfolios include pneumatic and electric grippers, Co-act gripping modules for collaborative applications, as well as quick-change systems. Whereas the pneumatic grippers are easy to use, have a high-performance density and are attractive in price, they are especially predestined for conventional automated applications, where primarily its robustness is sought-after. Electric grippers are flexibly adjustable to force or stroke, are versatile in use and offer many variants. Plugins simplify programming, particularly for those users who are new to automation, because they benefit from a fast and simple start into process automation.

Broad selection of components

The segment of pneumatically controlled actuators includes modular systems of the industry-proven, multi-tooth guided parallel gripper PGN-plus-P, the centric gripper PZN-plus, the universal gripper JGP with the best value for money, as well as the long-stroke grippers KGG, and PSH. Micro valves for control of the pneumatic modules are already integrated in the Plug & Work adapters. Moreover, the selection of components includes electric grippers for small components EGP, electric grippers type Co-act EGP-C, as well as the versatile SCHUNK EGH with a freely programable overall stroke of 80 mm: it is virtually the ideal gripper for starting cobot-supported automation. But the Plug & Work portfolio also includes the manual change system SHS with integrated air feed-through, electric feed-through and an optionally integrated lock monitoring. It allows flexible use of cobots, since laborious make-ready processes lapse, and the SCHUNK grippers but also other actuators can be exchanged in just a few working steps.

Diverse applications

The reason why cobot applications can be easily adapted to different application cases is that every component is flexibly combinable and the whole offering of accessory products and options listed in the SCHUNK catalogue, are available. Solutions can be intuitively configured with the SCHUNK online configurator, based on the eCATALOGsolutions technology of CADENAS. It takes just one click and all common CAD formats (optionally two- or three-dimensional ones) can be downloaded. Thereby a combinational logic ensures that only configurations can be implemented, which are feasible from a technically and mechanically point of view. The ready-to connect Plug & Work portfolios cover diverse fields of application: the ones of common automation but also of collaborative applications. They are equally suitable for people without any experience in automation and experts of the metal-cutting industry, automotive and electronics industry, logistics and of many other industries, who want to discover the potentials of robot-based automation by using cobots.