A complete assembly department

K.L.A.IN. robotics offers a varied catalogue of products and solutions for all the needs of today’s mechatronics, starting from different types of robots, to power supplies, up to vertical warehouses. Simone Brambilla, Key Account at K.L.A.IN. robotics, during his speech at the Assembly Week, provided us with an overview of some solutions dedicated to the world of assembly, also presenting some new products.

Let us break the ice by talking about the company: who is K.L.A.IN. robotics? Could you provide an overview?

K.L.A.IN. robotics, based in Brescia, was founded in 1999 and distributes robots for the world of factory automation and mechatronic components on the Italian and Swiss-Italian markets. Our activity is mainly divided into two fronts: the first is the distribution of automation components mainly to specialised system integrators, operating in the construction of assembly lines and special machines, in the handling and servicing of operating machines in general; the second is active service. The latter consists of various activities: simulations to check the cycle time or to identify the most suitable robot to use; basic and advanced training courses for programming our products; service on all the products we represent, thanks to highly qualified personnel and a warehouse full of spare parts; if necessary, we can use our software engineers to support customers who ask us for help in programming and optimising the robot program.

The new low-cost LPH series has been developed to meet the increasing demand for robots for low-demand applications.

Hyundai robots are available in capacities from 4 to 600 kg.

For over twenty years, you have been the Italian distributor of DENSO robots, which offers a wide range of assembly solutions. But what is the most popular type of robot in this sector? Among other things, we know that a “light”, or rather low-cost, version of the SCARA has been introduced; how will this affect the market?

We have been the Italian distributor of Denso robots for 22 years now. The DENSO range is definitely the most complete on the market, since we can count more than 800 codes if we consider all the multiple versions the brand offers us. In this respect, DENSO has always played a fundamental role in the assembly sector, where in the design phase of the lines there can be multiple options in choosing the most suitable robot to use.

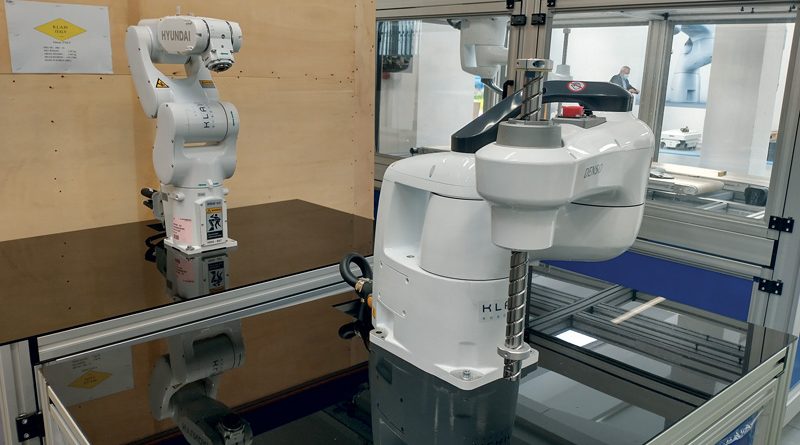

The DENSO range is divided into two macro families: SCARA and anthropomorphic robots. As regards SCARA robots, we can offer a range of robots with payloads from 3 to 20 kg, with intermediate payloads of 5, 8 and 10 kg, and reaches from 350 to 1,000 mm. The anthropomorphic robot range consists of machines with payloads ranging from 2.5 kg with 430 mm reach to robots with payloads of 40 kg and 2,500 mm working area. Within this range we can offer robots with payloads of 4, 7, 13 and 25 kg, with reaches from 500 to 1,800 mm.

Our range of DENSO robots comes with standard IP40 protection, and IP65/67, CC ISO3/5 protection are also available; we can have UL compliant robots and even have robots which can be washed with hydrogen peroxide and sanitised with UV light for drug preparation. To support the market even better, DENSO has also introduced a “light” version: the new LPH series of low-cost robots has been developed to meet the ever-increasing demand for robots for less demanding applications. The LPH series is the ideal solution for all those who are looking for a robot with the high quality characteristics guaranteed by the DENSO brand, but with a lower investment.

Besides DENSO, you are also a distributor of Hyundai brand robots. These range from large-scale solutions with capacities of 600 kg to 4 kg models. What is special about this range? What added value do they bring to assembly lines?

For the past 10 years we have been the Italian distributor of the Hyundai robot range, a brand known on the market for its large size robots, palletisers and anthropomorphic robots up to 600 kg. These robots are very useful in assembly lines, giving integrators, who are already loyal to Hyundai robots, the possibility of not having to change brands when they need to use compact robots, just as happens in assembly lines. Not only robots, K.L.A.IN. robotics is also a distributor of Eyefeeder and FlexiBowl feeders for use with DENSO and Hyundai robots. These two solutions are basexiBowld on the concept of flexible vibration.

KLAIN robotics also distributes EYEFEEDER flexible power supplies for DENSO robots.

MiR’s AMRs are therefore equipped with autonomous driving with load capacities from 100 to 1,350 kg.

What advantages do they bring to operators in the assembly sector?

For years we have also been a distributor of flexible power supplies, which for DENSO robots are the Mini Eyefeeder and Eyefeeder (because inside the latter there are two DENSO drives which optimise the robot-controller interaction). For Hyundai robots, on the other hand, we have started a partnership with ARS and its FlexiBowl feeders, so that Hyundai integrators can also use flexible feeders in the assembly and servo world.

We conclude by talking about intralogistics. In the K.L.A.IN. robotics catalogue there are both the MiR mobile robots and the Effimat warehouse: these two machines are able to communicate with each other, working essentially autonomously. How can this “collaboration” between machines be useful in the assembly sector?

We always try to understand what the automation market may require and after careful analysis, we have decided to expand our product family by adding two very important brands dedicated to the intralogistics sector. One of these is MiR, producer of AMR robots, which are equipped with autonomous control and have load capacities from 100 to 1,350 kg. Another very important product which we added to our catalogue is the Effimat warehouse, which can be used both as a buffer within a production process and for storing the finished product; it is not the classic vertical warehouse, but has special characteristics in that it automatically manages individual 600×400 mm boxes, managing up to 250 picks/hour.

Looking back at all the brands we distribute, we like the idea of thinking of an assembly department made up of each of them: DENSO and Hyundai industrial robots taking care of assembly and palletising at the end of the line, AMR MiR dealing with the logistics of the semi-processed product to be buffered in an Effimat warehouse while waiting to be picked up for further processing, or the logistics of the finished and packaged product, transporting the pallet to the department dedicated to shipping.

This simple and quick example shows how K.L.A.IN. robotics is a strategic partner for all system integrators and end users looking for someone who can provide them with a complete range of products dedicated to mechatronics.