Raffmetal launches Silval, the innovative range of green primary alloys

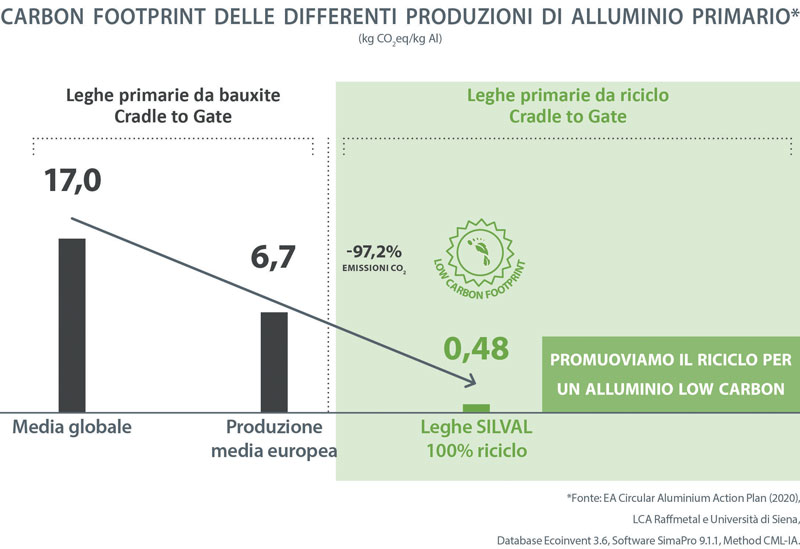

With a recycled aluminium content between 80 and 100%, Silval alloys offer a carbon footprint of up to 0.48 kg CO2eq/kg of aluminium produced and rank among the alloys with the best environmental performance on the market

Raffmetal confirms its commitment to the environmental sustainability of the aluminium industry and presents the new Silval range of primary aluminium alloys from recycling with a low carbon footprint and performance equal to aluminium alloys produced from primary metal. For Raffmetal, which with two production sites in Italy (Casto and Odolo, near Brescia) and a production capacity of over 300,000 tons per year is the largest European producer of aluminium alloys obtained from the recovery of aluminium scrap, this is a success which confirms the validity of a development process launched in 2018, with the construction of the new Special Alloys production plant, dedicated to the production of new primary alloys from recycling. The scrap metal, purchased in Europe and the rest of the world by a dedicated network, is stockpiled at the Raffmetal plant which, thanks to the best sorting and selection technologies, is able to separate the raw material from impurities and organic parts, as well as select it on the basis of the specific chemical analysis. This makes it possible to maximise the percentage of recycled content (between 80 and 100%) in the finished product and to reduce the amount of alloying agents for alloy correction, increasing the quality of the alloy and lowering the carbon footprint of the finished product. Direct control of the supply chain allows Raffmetal to cope with seasonal variations and possible market tensions, ensuring the availability of alloys with constant and repeatable metallurgical characteristics. A state-of-the-art smelting process combined with continuous casting technology ensures high quality ingots and metal yields, which are also guaranteed by a traceability system on every single piece.

Environmental performance measured from alloy to finished product

“In a context characterised by the need to take urgent action to preserve the planet and fight climate change, thus contributing to the European objectives for decarbonisation, Raffmetal with its core business wants to be a protagonist of this change, offering a quality, sustainable, circular product with a low carbon footprint. Silval alloys are actually designed to help our customers achieve their sustainability goals and meet the demands of increasingly environmentally conscious consumers,” says President Orlando Niboli. Indeed, the development of the new Silval range was based on an LCA (Life Cycle Assessment) study path which began in 2019 in partnership with a prestigious Italian University. The life cycle analysis led to the definition of the product carbon footprint of Silval 100% recycled alloys, using the ECOINVENT 3.4 database, SimaPro 8.5.2.0 software. The PCR (Product Category Rules) phase for the aluminium sector is now underway, which will lead to product EPD certification. This development path has been chosen to meet the specific requirements of the automotive sector, which is increasingly demanding recycled aluminium components capable of reducing the carbon footprint of castings throughout their life cycle. The LCA calculations followed the method most requested and used by OEM and Automotive customers, called cut off, in order to ensure a shared calculation methodology and continuity along the supply chain. The results of this study place Silval alloys among the best performing alloys in the market, with a carbon footprint value (Cradle to Gate) of up to 0.48 kg CO2eq/kg of aluminium produced.