Thermoregulation at the cutting edge of technology: HPDC by Gefond

HPDC by Gefond develops a complete line of multi-circuit water cooling and temperature control systems for light alloy foundries

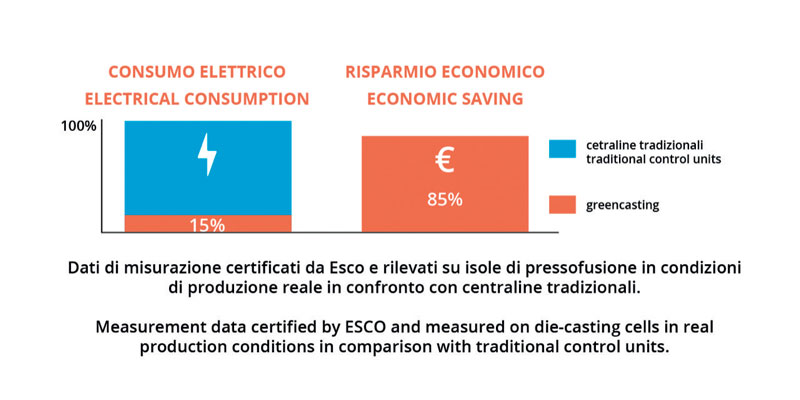

HPDC by Gefond produces water and multi-circuit cooling and temperature control systems for industrial applications. Based on Greenbox technology, HPDC by Gefond develops a complete line of machines dedicated to light alloy foundries. The HPDC by Gefond control units represent: sustainability thanks to the patented energy saving technology that allows to save up to 85% of electricity compared to traditional control units; digitalization thanks to the possibility to integrate on each machine Perpetuo, the software for predictive maintenance in the foundry; fundamental operational advantages in addition to energy saving such as longer mold life, better casting quality and cycle time reduction. All this translates into savings and increased productivity. The possibility of differentiating the thermoregulation in the various zones of the mould, combined with greater heat removal, allows the lubrication cycle to be reduced, thus increasing productivity and limiting the costs of waste disposal. In addition, an increase in productivity of between 12% and 14% has been verified, thanks also to the reduction in waste and downtime associated with mould maintenance. Last but not least, savings were made by eliminating oil from the process.

The complete HPDC line by Gefond:

• GreenCasting, 400 and 600: temperature control unit also ideal for minimal lubrication and structural castings.

• Greencasting mini, the concentrated power: energy saving and process optimization dedicated to cells with tonnage less than 1000 tons

• Greenjet for jetcooling technology: high-pressure multi-zone temperature controller for plugs and micro-channels.

• Greenshell for low pressure and gravity: multi-circuit systems with high cooling power.