Imago Vision Systems for the Die-Casting Cell

Mhira 3D, Anglerfish and Magpie are the three innovative vision systems created by Imago which act in an integrated way in the die-casting cell for the quality control of every single casting after the die-casting, trimming and machining phases

Modern die-casting products require specific, objectified and documented quality controls. For this reason Imago, a company with twenty years of experience in the Quality Control sector with industrial vision systems, in recent years has specialized in the creation of devices that allow to track all production and interact in real time with the machines in each individual phase, in order to guarantee an overall quality improvement.

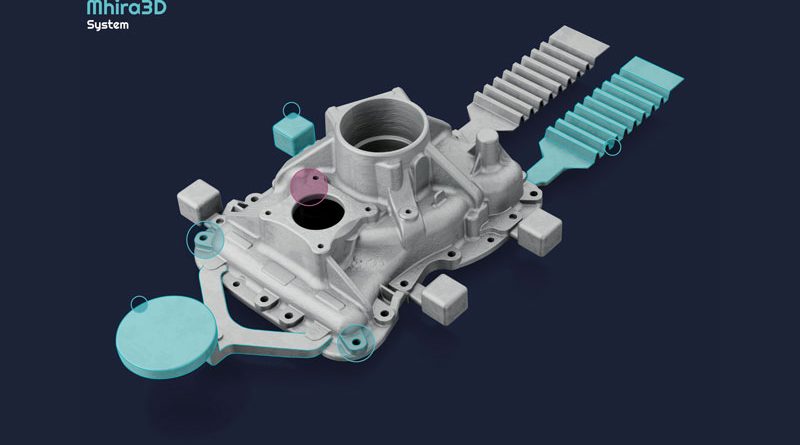

Imago has created three devices, to be inserted and interfaced in the die-casting cell, for carrying out the control of the single product after the casting, trimming and machining phases. Upon extraction of the piece from the press, Mhira 3D checks its integrity and, through a thermographic mapping, analyzes any thermal drifts. After the trimming phase, Anglerfish checks the deformations and breakages by inspecting the flatness and regularity of the cut surfaces.

Finally, Magpie identifies the porosities, the breaking of the edges and the residue of non-compliant burrs that may emerge after the machining. Magpie also carries out a total control at the end of the line that allows the customer to supply only compliant pieces. These systems offer significant advantages, which are not limited to the high precision of the results or to the innovative interfaces, but go further by providing, for each single piece produced, the possibility of storing data, the relative images and the machine setting specifications: information of value that can be interfaced with the company management programs to monitor and improve production.

The goal that Imago pursues and raises daily, for die-casting as well as for other sectors, is complete control of the entire production cycle, through the use of vision systems and artificial intelligence. The software developed by Imago meets the requirements of Industry 4.0 and guarantees the constant maintenance of a high production standard. The IoT, the network interconnection between machines, makes it possible to intervene in real time in the event of drifts and repeated errors due to variables on the machinery, by always available production data.