IDRA, Innovation and Strategic Growth in the Global Market

Idra Group is strengthening its leading position in large tonnage machines sector

by Roberto Guccione

Big numbers for 2019: Idra is currently building five 4200 tons OLCS die casting machines. Five large international groups have chosen Idra as their partner for the construction of large presses. This is confirmation of how the market considers Idra Group as the reference point for large-scale projects.

All five machines will be delivered during 2019, an impressive demonstration of Idra Group’s production capacity. Notably one of these will be the first OLCS 4200 to be installed in India, at the Bharat Forge plant at Mambattu, Andhra Pradesh.

OLCS cold chamber machines, ranging from 420 tons to 5500 tons of clamping force, are designed for high performance and consistent product quality. IDRA is constantly developing OLCS range, with innovative solutions designed to answer all the latest production requirements. The expansion of the machine range to include 5500 and 6200 is a response to the market requirement.

OLCS series gives excellent performance of the injection, combining high dynamic force with strong intensification for final pressure and complete flexibility of setting to give precise, stable production parameters. High integrity components for the automotive sector, including structural and Electric power train, can be produced with the highest guaranteed quality and productivity.

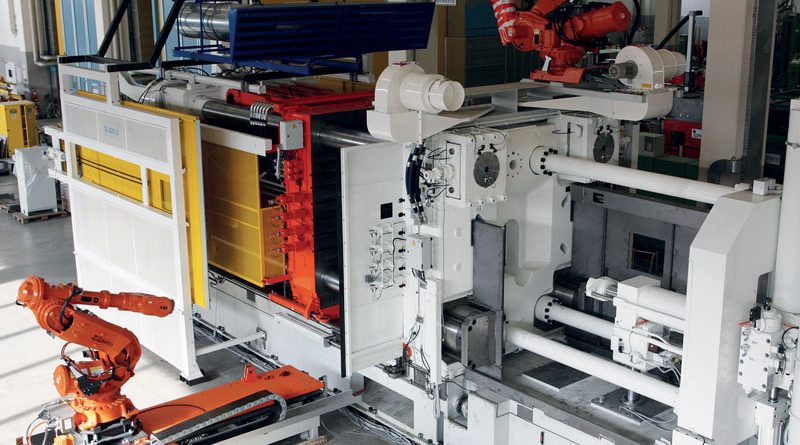

Awarded top supplier

The high level of Idra products and service is recognized by key customers. Škoda Auto (Volkswagen group) is one of the world’s leading car manufacturers, founded in 1923. The business relationship between IDRA and Škoda has reached another milestone, with the installation of the twentieth fully automated workstation of IDRA OL 2700 in the Škoda Foundry casting site. The new OL CS 2700 in the Škoda Foundry plant is a new paradigm for Industry 4.0 and automation. Its innovative thermoregulation concept and the online connection for the collection and evaluation of technical data parameters lead to shorter down time, increased OEE and increased die life.

Idra Group is a top supplier for Gnutti Carlo / Ljunghall / TCG Unitech Group and with the 2 most recent press machines ordered by Gnutti Carlo Group, the business relationship between the companies grows stronger, after a total of 16 machines supplied to Gnutti Carlo by Idra in many different countries.

As evidence of the high level of Idra products and service, the company obtained the prestigious Supplier Recognition 2018 award, delivered with great pleasure to Riccardo Ferrario, general manager of Idra Group, personally from the hands of Pier Carlo Gnutti – President and shareholder of Gnutti Carlo Group.

Gnutti Carlo Group, founded in 1922, is a global leader in the development and supply of valve train and fuel injection components, high-pressure die-cast aluminium components and lubrication and thermal management pumps for heavy duty engines as well as for the automotive industry. As of December 2014, Ljunghäll AB became a subsidiary of Gnutti Carlo Group. The company is based in Sweden with production plants in Sweden, Czech Republic, China and the newest plant in Canada. CG UNITECH is a subsidiary of the Gnutti Carlo Group from December 2018, with five locations in Austria and China with more than 1,100 associates.