APPLICAZIONI

Robot e laser, diventa tutto più semplice

Nextema aveva la necessità di far interagire l’operatore con il robot di tempratura laser senza dover programmare. Una sfida complessa raccolta dal system integrator Teicos, che ha sfruttato al massimo le potenzialità di Ignition, un’innovativa piattaforma software distribuita in Italia da EFA Automazione.

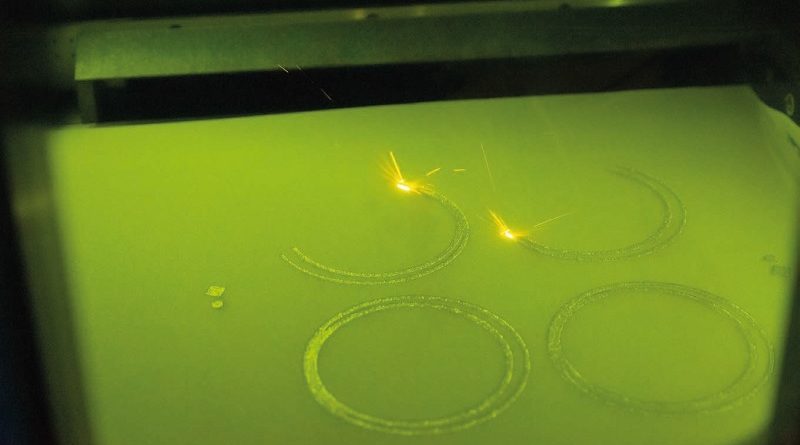

Insieme per l’additive manufacturing a letto di polvere

WeAreAM, RIDIX e TRUMPF hanno stretto una sinergia per sviluppare soluzioni innovative di prodotto e processo, in particolare nella gestione e sviluppo di leghe in alluminio, titanio, superleghe di nichel e acciai. Protagonista della partnership l’impianto TRUMPF di additive manufacturing a letto di polvere TruPrint 3000 doppio laser, equipaggiata da due sorgenti da 700W.

Tracciabilità e incisione laser dei componenti pressofusi

Il processo produttivo dei componenti pressofusi richiede l’inserimento dei requisiti di identificazione (individuale) per il 100% delle parti prodotte. Questo obiettivo può essere raggiunto tramite diverse tecnologie che analizzeremo in questo articolo, con un approfondimento particolare sull’incisione laser e sui vantaggi che la caratterizzano.

SOLUZIONI

Salvagnini innova il laser a 360°

Dalla nuova sorgente da 8 kW alta densità di potenza ad alto rendimento alle soluzioni avanzate per il controllo e l’efficienza di processo, Salvagnini prosegue nell’innovare la gamma di taglio laser, a partire dal modello L5 sempre più efficiente, flessibile e prestazionale. Novità anche per il laser L3 con i dispositivi di carico/scarico ADLU e di sorting automatico MCU in taglia 6020, ideali per la lavorazione di formati di lamiera fino a 6 metri di lunghezza.

CRONACA

Marcatura laser su misura, senza compromessi

RMU Marking presenta quali sono i tratti distintivi che caratterizzano il loro sistema per la marcatura laser Made in Italy, e come questo rappresenti la soluzione ideale per le grandi realtà produttive e non solo.

Arriva la fototermica laser

L’acquisizione da parte di Precitec di una quota di maggioranza della start-up francese Enovasense ha aggiunto una tecnologia ad alto potenziale al portafoglio del Gruppo Precitec. La tecnologia fototermica laser sperimentata da Enovasense è in grado di misurare lo spessore di tutti i tipi di rivestimenti, come metallo, ceramica, vernice, polimeri e colla, e su qualsiasi substrato.

Aspirazione per tutte le applicazioni

LAS 260.1 è il nuovo sistema presentato da PCB Technologies di aspirazione e filtraggio fumi laser, sviluppato per qualsiasi tipo di applicazione industriale. Si tratta di una soluzione potente, flessibile e semplice da utilizzare, che garantisce processi laser sicuri e puliti.

PROTAGONISTI

Lituania, la casa del laser

Incontriamo Gediminas Račiukaitis, presidente della Lithuanian Laser Association, per conoscere il percorso che ha portato la Lituania, un paese di neanche tre milioni di abitanti, a diventare un riferimento a livello mondiale per le tecnologie laser.