Kawasaki Robotics Is Celebrating Its 50th Anniversary

With Tiesse robots in Japan, where developments in the field of artificial intelligence were presented for operator training.

by Roberto Guccione

At Irex Tokyo, Kawasaki Robotics celebrated its 50th anniversary as a manufacturer of industrial robots. The half-century target was celebrated in an indoor area of about 1200 square metres within the event, where the Japanese company, a historical partner of Tiesse Robot, the company based in Visano (near Brescia), also introduced some relevant technological innovations, such as the two new RS7N and RS7L models and the new BX200X robot with a hollow wrist.

Kawasaki’s history began in 1968 with the signing of a cooperation agreement with Unimate and the supply of the first hydraulic spot welding robot in the automotive industry. In 1981, the electrically controlled Puma robots were launched and, in 1989, the JS series of robots with a capacity of 10 kg, which became a trailblazer for all other robot manufacturers, as well as the 165 kg EX Series robots.

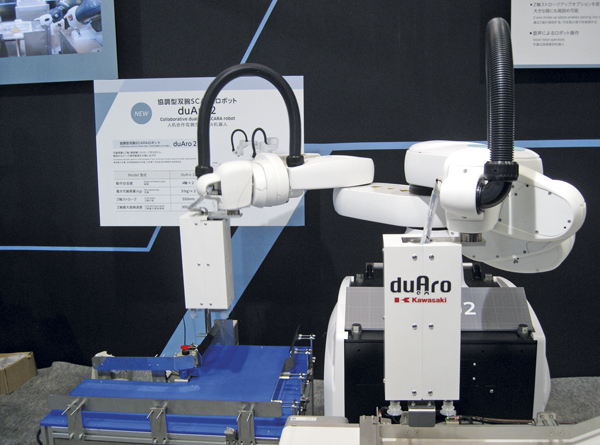

The Kawasaki range today consists of a much broader series of robots ranging from 3 to 1500 kg capacity, with specific robots for the medical-pharmaceutical sector and clean-room. The Japanese giant intends expanding its range of collaborative robots with the Duaro 2 and Duaro 3 models, even by signing a cooperation partnership with ABB for the joint development of safety and communication protocols.

At the same time, Kawasaki intends developing a concept of Coworking between robots and operator called “Successor”, based on combining robots with remote drive devices and artificial intelligence packages which enable specialized operators to transfer their skills to the robots themselves.

In practice, by means of a device known as “Communicator”, the operator may move one or more robots on the same line for operations which in reality would require a high level of programming skills; this may be done by simply acting on the device which, in return, provides the operator with the same “feeling” as the robot in the operation being carried out; for instance, a sensation of “force”, of “vibration”, or sound alarm signals, if the robot is forcing or interfering. Having performed an operation, the robot repeats its sequence and process exactly. Artificial intelligence then allows the robot to transfer what has been learnt by a specialized operator to another non-specialized operator, therefore not having the same competence. The applications which such a robotised work station may deal with are many, ranging from the assembly to the coating of small or large details, right up to the handling and deburring of castings, and so on. Further development of this technology will also allow, using simulators, to carry out training for non-skilled operators, who will learn through the use of the same robotised machines.

A new field concerns humanoid robots, the first prototypes of which have been presented, and integrated solutions for surgical theatres, thanks to a joint-venture with Medicaroid, which will bring onto the market 6-7-axis surgical tables and surgical robots with 1 to 4 arms, as well as robotic solutions for CT and localized treatment of cancer with focused radiation.

Further innovations will be presented during the year 2018, as a demonstration of the Japanese manufacturer’s capability of innovating.