Metra, the Added Value of Extrusions for Building and Industry

From the foundry to the machined and assembled subgroups: the full integrated supplier strategies of Metra, focused on sustainable quality, logistics, flexibility and time to market, in an exclusive interview with the CEO Enrico Zampedri

We met Enrico Zampedri, Managing Director of Metra, one of the first non-integrated aluminium extrusion companies in Europe, in the Rodengo Saiano offices. Founded in 1962, it was one of the creators of aluminium profile window and door systems in the mid-1960s, soon expanding its activity to the design and production of custom profiles for industrial uses intended for the most diverse applications. Precisely to meet the needs of the industrial sectors, Metra, at the forefront among private extrusion companies, soon equipped itself with a press having a great thrust force – 6,000 tons – for the production of large-sized extrusions. A company path full of facts and choices, whose distinctive element is the constant attention dedicated to the market, aimed at creating innovative products and applications as well as communicating, informing and educating to stimulate the growth of the market itself. First of all, we asked Mr. Zampedri how Metra has taken up the great challenges of this last period, reaffirming and re-launching its role as a leading player, with the strength that comes from over 60 years of experience in the sector and thanks to the valuable knowledge acquired on the global market.

“Time is running fast today – markets, technologies, ways of communicating and commercial relations are constantly changing. The first step we took a couple of years ago when I joined Metra was a patient and meticulous review of the company structure. From there we set up, with the help of Roland Berger Global Consulting, a 2020-2024 organic plan for strategic development, starting from the reorganization of the two aspects which characterize Metra, Building and Industry. The objective was to make the most of our capacity in the production of high quality aluminium extrusions, which we supply complete with finishes and additional machining, through significant design added value in the two macro-areas of architectural uses and applications in the various fields of industry. Ettore Bonetti, Head of the Building Division, and Alessandro Giacomelli, Head of the Industry Division, will be able to illustrate in detail the peculiarities of the two segments, which differ in terms of product types and customers, but share the company’s vision of considering extruded aluminium as a raw product to be enriched with innovative design values in partnership with users, in our own interest as well as that of customers and the market”. We therefore asked Ettore Bonetti to provide us with a picture of the activity of the Building area, which has been Metra’s prevailing image on the market for many years.

“The building and architectural segment is still of the utmost importance in Metra. Within this Division we now have two very distinct aspects: on one hand, Systems, that is, the architectural series for doors and windows, a classic product but one which in our company is constantly evolving from an aesthetic and design standpoint; on the other hand, the Custom area of Large Projects, where Metra’s historic competence in aluminium in architecture combined with production flexibility and technical ability to co-design with clients is an asset. Our strong point is the absolute integration between these two areas: the innovative project can derive from the long experience accrued in the standard product, and vice versa the standard series continuously benefit from the new knowledge acquired in the original great architectural and building creations in aluminium which we contribute to create. This continuous exchange of data and information within our system means that we can always work close to the needs of the market. Not all companies have the same opportunity and the same wealth of knowledge behind them as Metra. We have also developed the assembly of architectural subsystems within the Building area, to support curtain wall builders who can take advantage of Metra Service’s know-how in especially on projects of significant dimensions. Basically, we increasingly offer our services as technical and design partners at 360 degrees. Facts prove us right and in the last two years, before Covid-19, the Building Division has grown by 20%”.

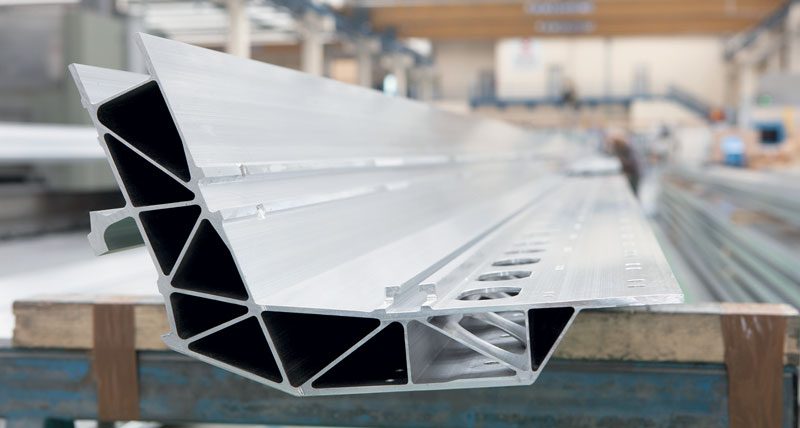

Alessandro Giacomelli, head of the Industry Division, added: “The other production segment is precisely Metra Industry, which means extrusions of every shape and complexity for the most diverse uses in the various industrial sectors, from transport to mechanics, from design to electronics, pneumatics, furnishing, heating, and various types of structures, produced with alloys ranging from soft to high-resistance alloys for structural uses. The wide range of extruded products offered goes as far as large-sized profiles produced with the 7,500 t press, starting from billets weighing up to 700 kg and 2 metres in length. It is clear that the applications of extruded products in industry cover an infinite area of metallurgical and technological opportunities; in this field the design expertise we can guarantee our users plays a fundamental role, with the added value of being able to supply machined profiles up to 29 metres in length. Machining is one of the activities which we developed the most in recent times and one to which we have dedicated and are dedicating great attention, doubling our capacity over the last two years. The last step taken in this direction is the installation of a brand new line for welded subassemblies, which completes our services, which today range from the foundry to the welded subassembly, according to the One Stop Shop principle, and which allows us to define Metra as a true full integrated supplier, with obvious advantages in terms of logistics, flexibility and time to market. Delivery times to the end customer are shortened, the transport of profiles of exceptional dimensions is reduced with a clear and immediate positive impact on the environment, a product with high added value is supplied in very short times. This is a decisive leap forward that brings us significantly closer to our customers. An operation involving an investment of over 6 million euros, which will be completed by the end of the year”.

Mr. Zampedri, how would you comment on this picture in terms of company data and prospects?

“In a nutshell, we have quickly and without hesitation adapted the company’s organisation to the demands of the market, with all the flexibility and determination which characterise Metra even in difficult times like the ones we have gone through and are still going through. The interventions have been articulated within the operational lines described by the managers of the two divisions and the innovative initiatives implemented within the company have been appreciated by the market, as shown by the financial results for the years 2018 and 2019, with a turnover of around 270 million with Ebitda close to 11%. Today Metra has a solid financial position, and can afford to continue to invest significantly.

With a total production volume of around 57,000 tonnes of semis last year, we represent around 10% of the market in Italy and over 1.5% in Europe, and we have managed to strengthen our share in a declining market situation. As for the short-term outlook, we have suffered like everyone else from the Covid-19 effects, but I have to say that we are confident that we will be able to get away with a 2020 result not far from that of 2019. We are satisfied with the balance of our current production mix, which is divided roughly in terms of volumes between 65% in the Industry Division and 35% in the Building Division. The export share is also significant and satisfactory: we send about 50% of our production directly abroad, and indirectly, that is, considering those Italian customers who are themselves exporters, the figure rises to about 85%. In the current market situation, with frequent and sudden variations in demand both on the national territory and on the foreign markets most interesting for us, our wide production mix allows us to manage our workload in the best way and without difficulty”.

Speaking of foreign markets, what can you tell us about your activity in Canada?

“The Canadian production unit, as well as accounting for 20% of our group activities, which is no small thing, is a strategic presence for the entire North American market; the recently established subsidiary Metra USA is now only a sales representative, but it is destined to grow in our 2020-2024 strategic commercial and production plan . We are studying targeted actions to effectively penetrate the American market, on which we shall introduce ourselves with important and high-impact achievements”.

Let us conclude with a quick comment on the world of aluminium, which is proving to be a highly strategic sector in the new sensitivity to the industrial renaissance of the European Union. Light metal is in fact seen as the basis of the manufacturing system to provide it with competitiveness and the ability to create jobs, for the many positive aspects that characterize it, from the ecological one, to sustainability and social value as a champion in recyclability, in the commitment to protect the environment and energy resources and the attitude to develop the circular economy.

What do you think of this extraordinary interest in our metal?

“In this climate marked by a strong collective effort to react to the tragedy of the pandemic and the will to relaunch the industry, it is very significant that the European Commission’s ambitious Green Deal programme recalls in various points the green aluminium and more or less directly the small and medium-sized European manufacturing companies which form the heart of the specific production segment. We are undoubtedly very pleased to note this very positive message for the use of light metal”.

I believe that it is in everyone’s interest to enhance the most virtuous technologies and materials, and it is a good sign in this regard that a strong movement of opinion is being created to prefer the use of green metal with a low CO2 footprint, with programmes on which many of the world’s leading primary producers are working. From our point of view, we have great confidence in the future development of light metal, and I believe that once again Metra has shown that it has a very solid base in this production segment, even in difficult times, and that it is a point of reference for expanding the size of the aluminium business, with positive effects for the entire system”.