Aluminium Packaging Conference, an opportunity for training and discussion even online

The traditional conference dedicated to aluminium packaging organised by the Italian Packaging Institute took place this year in webinar format, confirming the ability of the sector to propose innovative and sustainable solutions.

It was February 20th, 2020 when the annual conference “Aluminium Packaging”, organised by the Italian Packaging Institute and moderated by its vice-president Ciro Sinagra, was held in the traditional location of Florence. We were just a few hours away from a historic change. A year has passed and on February 18th, 2021, due to the pandemic, the first online version of the conference was held. Many things have changed, starting with the webinar format, the most correct one given the times, but one that fails to dispel the nostalgia for a physical event. Other things have remained the same, starting from the excellent moderator, a few speakers and the excellent level of the slides accompanying the presentations.

Ciro Sinagra’s introduction reminded participants that the pandemic highlighted the need to focus on the role of aluminium in the European Green Deal. Aluminium is a key raw material for the greenhouse gas emission reduction targets of the next Green Deal, so much so that a ‘new’ raw material should emerge, with its own brand (Green Aluminium) and its own market price.

The packaging industry will have great responsibility in the further development of the secondary metal, thanks to the high recyclability achievable with appropriate design adaptations.

In the beverage industry, aluminium is the most sustainable alternative to plastic

Within the packaging sector, the largest amount of aluminium is used in the beverage sector, in the form of cans, lids and bottles. Claudio Scarmagnani of Ball Beverage Packaging Italia described the range of different products. While in the past the market focused on a few can models, there is now a wide choice of shapes and volumes from 250 ml up to 1000 ml with different diameters and types of closures (figure 1). In addition, there are resealable bottles obtained by a process of drawing and stretching of thin sheets, as for cans, or produced by impact extrusion of aluminium discs. The former may have a screw cap while the latter must be closed with a crown cap (figure 2). The aluminium beverage packaging industry is faced with the potential replacement of the approximately 93 billion disposable plastic cups and mugs used each year worldwide, which will no longer be allowed for use in the near future. One possible answer is the easily recyclable or reusable aluminium cup (figure 3), which Ball introduced in the US in 2019 with a pilot project focused on major sporting events, receiving a very favourable response from consumers. Aluminium products in the beverage sector offer the best potential for recycling: they are the most recycled packaging product in the world; they are essential for the exemplary development of a circular economy; they are characterised by a short return time to re-melting centres; they contain on average about 70% recycled material; 75% of the aluminium produced historically is still in use.

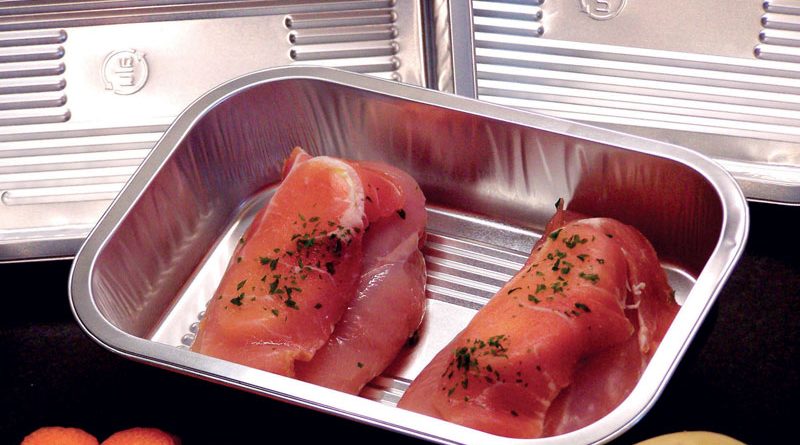

Aluminium and food

An obstacle to the development of aluminium packaging in the past has been the limited availability of data on the behaviour of the metal in contact with food. Today, the situation has radically changed and this improved knowledge has also led to the definition of standards and laws in different countries. The memoir presented by Raffaella Bonacina, Quality Deputy Director & Food Contact Expert at Carcano Antonio Spa, and the references made to the most important legislations, make the memoir itself a working tool to be kept in mind in order to deal with the complex issues in the relationship between container and content. Barbara Iascone from the Italian Packaging Institute presented the Institute’s recent statistics on the Italian packaging market, which is worth around 40 billion euros. The weight of aluminium packaging is small, about 200,000 tons/year or about 1% of the total, but the value is almost 10% of the total value of packaging produced in Italy, as shown in figure 4. Paolo Masciotta of SLIM Aluminium presented and discussed the production process of aluminium foil, examining the criticalities of the different phases of the process illustrated and summarised in the diagram in figure 6. Stefano Stellini from CiAl recalled once again how aluminium packaging, thanks to the infinite recyclability of the material, is an excellent “green” solution. It is therefore of fundamental importance that they may be appreciated for their environmental qualities and benefits, so that they may be perceived/mentioned/inserted among so-called “good” types of packaging in the discussions and in the different regulatory provisions which characterise the decision-making process for drawing the lines of the country’s ecological transition. It is therefore necessary to use communication to inform and raise awareness among public decision-makers and in this regard Stellini illustrated the new communication campaign promoted by CiAl, which emphasises that aluminium packaging is “responsible packaging”.