Kind & Co, Specialist in Extrusion and Die Casting Mould Steel

The quality of extrusions and die castings is directly influenced by the choice of the special steels used in the construction of the moulds and dies. This is explained by Giuseppe Colombo, CEO of Kind Special Alloys Italia

Kind Special Alloys Italia (KSAI) is the Italian branch of Kind & Co, a family owned German steel plant, active in the tool steel sector, in particular for hot–work tool steel and high-temperature resistant steels. With more than 130 years of experience and 400 employees, Kind & Co is one of the few companies in the world that has the entire production chain within it: steel production, forging, heat treatment, machining, stocking and cutting service. Main application segments are die casting, extrusion, and closed die forging. The company has been present for many years internationally with its own offices and branches. In Italy, the presence in the second largest European market in the field of aluminium production and in the first market in the sector of the production of extrusion dies is an important part of Kind & Co’s overall business: Ready-for-installation containers, parts and die steel for extrusion presses of aluminium and metals in general, tailored steel solutions for dies and moulds dedicated to die casting and steel for forging. The company contributes significantly to improving the competitiveness of the products of Italian companies in this strategic sector.

Giuseppe Colombo, CEO of Kind Special Alloys Italia explained: “Looking at solid business trends, demand for high quality hot-work tool steel is increasing, e.g., thin-wall profiles, sticky Al alloys, surface quality, dimensional stability, sealing surfaces. Tailored solutions including premium tool steel from Kind & Co can help to reduce production cost through longer service life. The initially more expensive material quickly pays off in terms of tooling lifetime, reduced maintenance steps and end products aesthetics. Of course, we also provide good standard steel, where the alloy content is standardized, but we at Kind & Co execute melting, forging, heat treatment excellently – that is why we call it ‘good standard’. Even if we are currently experiencing significant challenges in many end segments, we still focus on developing competitive product and process innovations with our clients. Quality matters! We continue to expand our service and value creation even in current, difficult times”.

What are the characteristics of your steel that makes it preferable to others?

“We are since many years among the international leaders in hot-work tool steels tool. We have a portfolio of high performing tool steel we can customize according to customer and internal best practices, by having an integrated and unique set of industrial and technical capabilities along the value chain, from melting to machining, within a mid-size flexible operation network. Application and metallurgical experiences in running the business are the pivot for supporting business development in old and new segments. Technical knowledge continuous upgrading is a pre-requisite for our sales team. Our steel grades are perfectly fitting the Italian customer base, even niches and sophisticated and demanding customers. Some examples:

TQ1 for extrusion dies is an industry benchmark now for many years. International aluminium extrusion and die casting companies are really committed in operating with dies&tools made in TQ1. In recent years, this steel is largely adopted in dies for large structural automotive components, castings with pronounced cooling fins, complicated dies for automatic gear boxes, components for e-powered vehicles (such as battery case).

CS1 has been recently introduced to answer to increasing requests for advanced demands to surface conditions. Visible parts of motorbikes, automotive cylinder head covers, parts for laptops, mobile phones and high end consumer products are items which can largely benefit from a specialty steel characterized by high temperature strength, excellent toughness even at elevated working hardness (up to 54 HRC possible).

CR7V-L is a versatile steel for hot and cold work applications: drop forge die and die inserts for forging presses, in steel processing, especially with serious wear problems, hot forming tools (hot stamping) of structural automotive parts, hot shearing blades and flash trimmers, push bench rollers for the production of seamless steel tubes and production tools for seamless steel cylinders. All applications where Italian clients and the related industry are among top global leaders”.

And what about the press containers?

“The container is one of the main elements of the extrusion process, therefore in the first place the choice of the project, its layout and, precisely, the choice of steels are fundamental elements. To make it very simple: it is not enough to bore a ‘hole’ in a block of steel, because this can create huge problems in terms of internal tensions and therefore subsequent processing. The coupling of different steels between the internal liner, the intermediate liner and the casing of the container, a design combined with appropriate cooling systems, require suitable materials and in this case make a huge difference, especially in terms of durability of the container itself. Our customers can have one less spare container, reducing maintenance, welding, and relining costs. In the case of the production of extrusions, the reduction of the risk of long and expensive production stops is particularly important. Kind & Co starts from the customer’s drawing and can supply the finished container with special forged steels”.

Who are your typical customers in the case of press containers?

“We are known for ready-to-install extrusion tooling (containers), relining service, heating system installation, accessories such as liners, mandrels, dummy blocks, cleaning disks, die holders, die steel and engineering and design optimisation together with the customer.

Our main customers are in two categories, the first being that of press manufacturers. In practice, these manufacturers produce all the main parts of the presses while they turn to us for the supply of complete containers. The second is that of extruders directly. I add that aluminium containers are an important part, but the extrusion of other metals, copper, brass and even steel are equally significant, especially for the Italian market, world leader in these sectors. Normally extruders buy their own containers independently, especially to better adapt them to their production characteristics. In this case we can carry out revamping operations on the containers, or supply completely new elements according to the drawing. Our client’s project is analysed by us modelled in 3D with computer simulations. In the case of containers, the type of steel used changes radically according to the type of production of the extruder. For example, the technology and construction design for direct presses are quite different from those for the construction of containers for indirect extrusion. The specialty of KSAI is to offer a choice of steels for the liners and all the parts that make up the containers and the tooling in steel for the presses, from casting, forging to machining and heat treatment”.

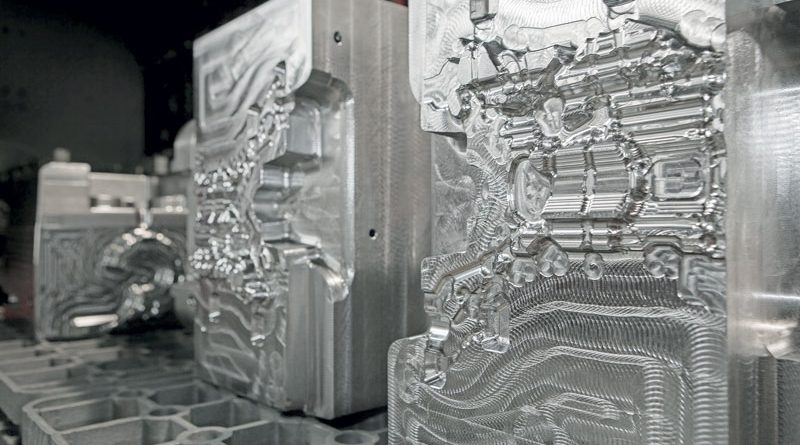

And what about die casting moulds?

“The characteristics are similar, of course there are steels for simpler moulds and steels for overly complex moulds. Very sophisticated moulds with complex processes, many holes, profiles, corners, etc. The good standards already mentioned are proposed for simpler moulds, while the special steels TQ1 and CS1 are the high-end products, which, for diecasting moulds that can cost several hundred thousand Euros, are indispensable. The cost of the material is relatively insignificant in the final calculation and for expensive moulds the savings on the steels to be used is simply a nonsense. An economical die casting process requires reliably working dies. Tool-related interruptions in the casting process or disproportionately high reworking costs for the products have a direct effect on the production costs of the cast parts. Our tool steels, manufactured under optimized production processes, offer special and high-quality properties regarding thermal shock resistance, high-temperature strength, toughness and wear resistance.

Choosing the right hot-work tool steel extends the life of the tool and improves the quality of the final product. Our specialty is precisely to provide our customers with superior technological solutions, to help them in competing, especially in segments such as the automotive sector, subject to radical transformation due to new propulsion and power systems”.

How are the different sectors you follow divided in terms of percentage of turnover?

“Die casting is our core business and represents approximately 30% of our total turnover, 30% is represented by extrusion steels, then dies, containers and tooling for presses, finally 20% dedicated to drop forging. Hot stamping, tube technology, glass processing, plastic moulds are also significant business contributors. A growing part of revenue is also coming from industrial and niche applications, from medical to food, indexable tooling, telecom”.