Specialists in the production of food push-fit fittings

Over the years Aignep has developed a complete range of fittings for the food industry. Nine lines of fittings are manufactured in total hygiene and health safety at the factory in Bione, near Brescia, in a wide variety of connections, sizes and materials. With this program Aignep meets the requirements of applications where the contact with the fluid is direct (coffee machines, vending machines or bottling machines) or indirect (PET blowing machines, bakery ovens or food packaging lines and so on).

The protection of public health underlies current international regulations concerning objects and materials in direct or indirect contact with food, a principle which Aignep has shared over the years and that allowed the Brescia-based company to develop a complete range of food fittings.

There are 9 lines of food fittings manufactured in total hygienic sanitary safety of the Bione plant, in the Brescia area, and that enjoy NSF international certification and MOCA IT/EU conformity. Inspections are periodically carried out by the bodies in charge to ensure the compliances acquired. A special plan for traceability of the components and the implementation of good manufacturing practices are mandatory. The choice of materials is among Aignep’s priorities and is very often carried out in cooperation with suppliers and certification bodies. The company uses 316L stainless steel or special low-lead brass alloys such as CW510L. The gaskets used are food contact compliant, while the plastic components use the PPSU compound, which is optimal for high temperature food applications.

At the end of 2020, Aignep opened a modern laboratory to thoroughly verify and test the quality and performance of the materials used. Every test carried out in the laboratory is aimed at improving the product. With the support of special equipment, life cycles are simulated both in standard working conditions and in aggressive environments or extreme situations. Many Italian and international manufacturers have already incorporated Aignep food fittings in their devices, such as coffee machines, vending machines or bottling machines, where the contact with the fluid is direct. Aignep fittings are also increasingly chosen for indirect contact applications such as PET blow moulding machines, bakery ovens or food packaging lines.

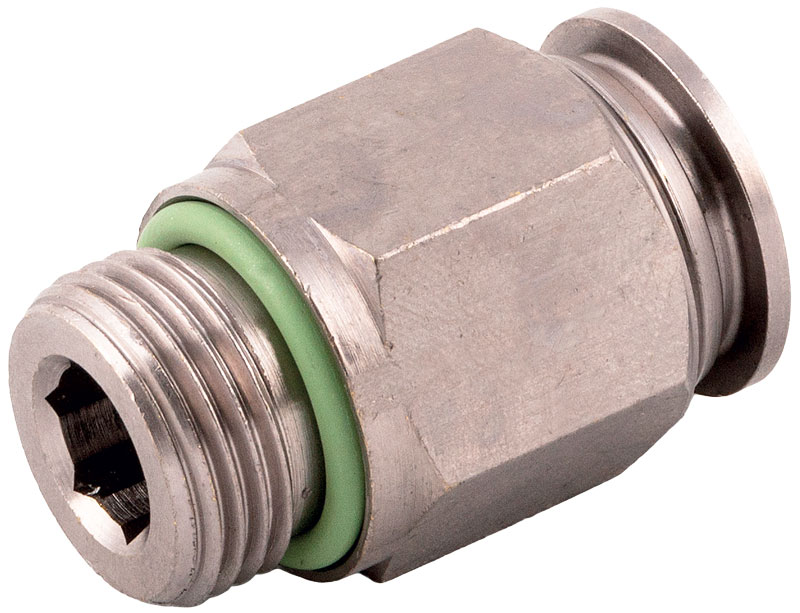

Thanks to a special surface coating, 70000 series fittings do not release any harmful substances into foodstuff.

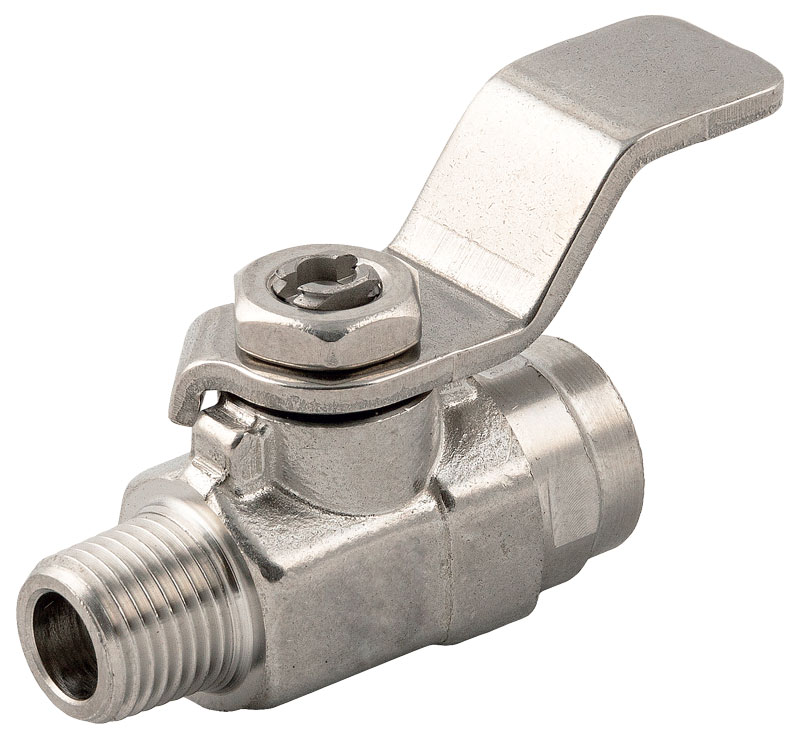

With the Ghinox series Aignep offers mini ball valves featuring compact dimensions, made entirely of AISI 316L.

The first NSF-certified line of food fittings

The 70000 series was the first food-grade push-in series developed by the company. Thanks to a special surface coating, the fitting does not release any harmful substances into foodstuff. The series is suitable for low temperature applications. This line has NSF certification for standards 51 and 61; one of the largest independent certification bodies has certified that these fittings can be used in all devices directly in contact with all foodstuffs and drinking water.

The 70000 series is made of lead-free brass, coated with a special non-toxic surface treatment. All gaskets are in food grade FKM, while the crimping tool is in AISI 304 stainless steel. The guaranteed operating pressure starts from -0.99 bar (-0.099 Mpa) up to 15 bar

(1.5 Mpa). A great advantage is the temperature range which, depending on the application, can reach up to +200°C (+392 F).

The 70000 series is available in the most common configurations and sizes for the application area.

Aignep’s range of stainless steel components.

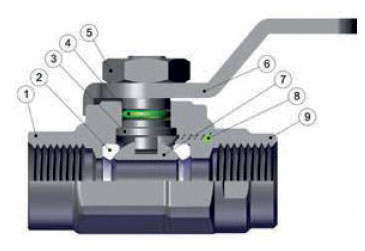

Ghinox mini ball valve technical features 1 Stainless steel AISI 316L Body; 2 PTFE Seats; 3 Stainless steel AISI 316L Spindle; 4 FKM Seal O-RING; 5 Stainless steel AISI 316L Hex Nut; 6 Stainless steel AISI 316L Spindle; 7 Stainless steel AISI 316L Ball; 8 FKM Seal O-RING; 9 Stainless steel AISI 316L Fitting.

A wide range of connections, sizes and materials

The variety of connections, sizes and materials make the Aignep range of food fittings particularly rich. The 59000 push-in series is produced in low lead brass alloy, certified for use with drinking water in compliance with the Ministry ‘s Decree number 174/2004 – regulation 98/83/EC. The same materials are used to produce the threaded fittings line called CW510L accessories. These lines are particularly suitable for the vending sector, thanks to the very interesting quality/price ratio.

Six lines of stainless steel fittings for the most aggressive sectors

For the most demanding or aggressive sectors, however, Aignep offers 6 lines of stainless steel fittings. The 60000 push-in series, specifically, is available for metric or inch pipes, with cylindrical or universal threads. In 2020, it was enhanced with new configurations and sizes. It offers very high corrosion resistance and a clean design thanks to the new Smart-Injection technology. For aggressive environments with high vibrations, the 61000 push-on series is available, designed to withstand high traction and ensure total sealing. If pressure rises and metal pipes are used, the 69000 compression series is the best choice. These two lines are also popular for applications in the chemical and medical industries.

The 59000 push-in series is produced in low lead brass alloy, certified for use with drinking water.

The 63000 series is a Multisocket system, allowing the 4 main quick connect profiles on the market to be connected.

Mini stainless steel ball valves

With the Ghinox series Aignep offers mini ball valves featuring compact dimensions, made entirely of AISI 316L stainless steel in the super-compact version.

The gaskets are made of food grade FKM. The Ghinox series is equipped with female-to-female or male-to-female connections. The ends are RP ISO 7 threaded.

The temperatures to which these mini valves can be subjected vary from -15°C to +150°C continuously or +180° intermittently. Their use is recommended for plant engineering sectors such as chemical, food and industrial plants. These products are manufactured in accordance with the EN ISO 9001 quality standard and EC Directive 1935/2004. Let us conclude with the 62000 series of stainless steel threaded accessories and the 63000 series, consisting of a Multisocket system, allowing the 4 main quick connect profiles on the market to be connected with one single tap. Aignep also offers as standard the European DN7.8 plug.