New Online Tool Enables Customized Safety

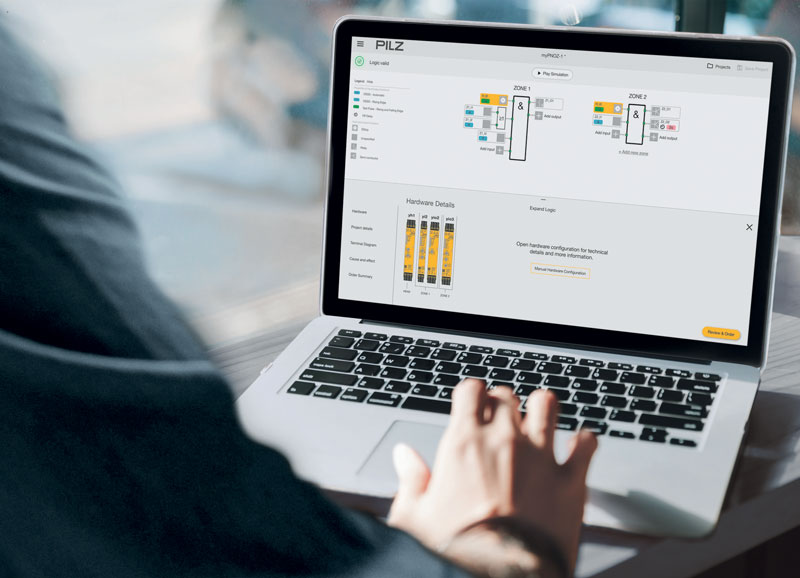

For its myPnoz safety relay, Pilz has drawn-up a universal, digital concept – from selection to ordering to commissioning. Thanks to the simple and intuitive online tool myPNOZ Creator, users can assemble “their own” myPNOZ, which is delivered pre-assembled, configured and tested: a system, therefore, ready for installation and fully customized … even in individual batch size 1.

Pilz’s myPnoz safety relay, available in several configurations, is used to safely monitor functions on machines, such as E-STOP or two-hand control on presses. In order to offer such tailor-made safety, Pilz created a universal digital foundation: the aim is to work with customers to manufacture their individual automation product. Thanks to the simple and intuitive online tool myPNOZ Creator, users create “their own” myPNOZ, which is delivered pre-assembled, configured and tested: a system, therefore, ready for installation and fully customized.

Countless possibilities, one product

The first step sees users record their requirements online via the corresponding online tool myPNOZ Creator. In myPNOZ Creator, users assemble the complete solution to meet their requirements from a wide range of possibilities. Users then have a tailor-made product: the logic operations for the safety functions are pre-defined via the plug-in sequence; no software knowledge is required. myPNOZ is delivered ready-to-install. A streamlined configuration and installation process is another highlight of the product. Thanks to a continuous, automated workflow, the specifications and all other information pass without media clashes from order to production and then dispatch. Here too, Pilz is committed to decentrality: the product is assembled from semi-finished products, fully configured and undergoes final tests either in the production plants or, if necessary, directly in the delivery warehouse. Within the shortest time scale customers have “their” myPNOZ – ready for commissioning. All that’s needed is a screwdriver for control cabinet installation.

The assembly process in the detail

Depending on the safety requirement, users interconnect safety functions such as E-STOP or safety gate using logic AND/OR connections. myPNOZ Creator uses a symbol to indicate any logic errors in the safety function sequence. Users can add any further safety functions at will and also define details, such as delay-on energisation and delay-on de-energisation for example. Users can check immediately whether a circuit or safety design meets their own requirements in the myPNOZ Creator, using the simulation in the online tool. As a result, errors can be reduced and commissioning accelerated. With myPNOZ Creator it is possible to define the number, type and logic connection between the safety functions, based on what customers need for their plant. The Creator uses these details to automatically calculate which modules are needed and the sequence in which they must be inserted. The plug-in sequence results from the connection logic for the safety functions. Due to this internal combination logic, the process requires no programming knowledge. The product that is generated can be ordered directly via the online tool, and users can order a previously defined configuration of myPNOZ with just a click of the mouse. The safety relay is delivered pre-assembled and ready to install. Each myPNOZ is given a unique type code, so that, if necessary, the same system configuration can be re-ordered at any time.