Flexible, maintenance-free solutions for the food processing industry

SKF contributed to strengthening Boema’s leadership in the field of food processing machinery. The SKF Food Line ball bearing units, designed specifically for the food industry, are completely sealed and certified to offer food protection as well as being maintenance-free and high-performing even in the toughest cleaning environments, where hygiene is an essential requirement. Furthermore, no relubrication is needed.

Food processing is a competitive industry. A machine manufacturer must not only design top-notch equipment but must also adapt to new government regulations, changing consumer tastes and increased societal attention to health and hygiene. Boema S.p.A. has been designing and manufacturing food processing machinery since 1979. At the beginning the company decided to focus on the peeling and processing of chestnuts, a heretofore ignored niche market, and invented machinery specifically for chestnuts. It became their calling card, their designs for this machinery are still used today and Boema is now recognized as a major global player in this sector. Later on, the company gradually expanded to non-seasonal secondary products such as purees, jams, frozen and fresh-cut food and baby food.

An extremely gentle process preserves the organoleptic properties

Another step forward came when the company introduced steam peeling. Boema wasn’t the first to use steam in potato and vegetable processing, but the company’s solution allowed for a more delicate handling of the product, a competitive advantage for fruit.

Today the company’s strategy of ad hoc customized projects, calling it an advantage. Every project is moulded “to customers’ specific needs; and the company is increasingly focused not on a single piece of machinery but on the complete production line.

The implemented solution is free from maintenance and relubrication

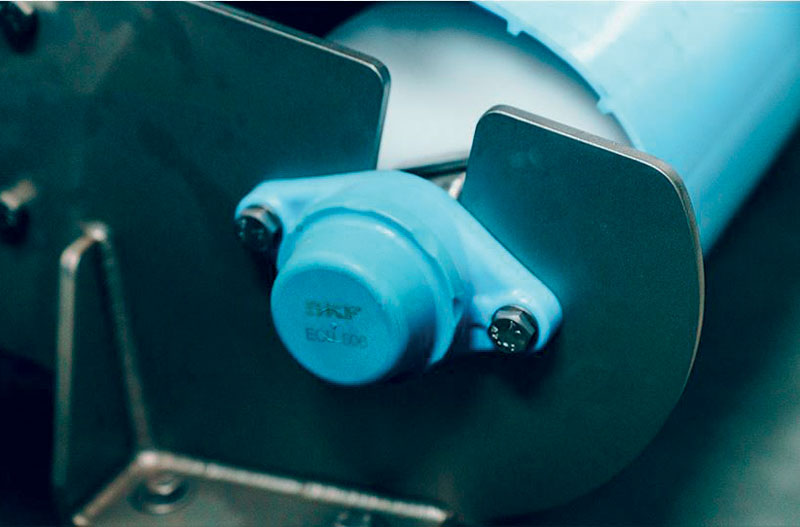

Boema has been purchasing SKF bearings, as well as lubricants, through an authorized local distributor, Crosa, since the early 2000s. One of the new products presented was the SKF Food Line ball bearing units, a series of bearing units launched that year designed specifically for the food industry. Its innovations were appealing to Boema: the bearings are completely sealed and certified to offer food protection as well as being maintenance-free and high-performing even in the toughest cleaning environments, and no relubrication is needed. No lubrication means that no worker is exposed to potentially dangerous situations working in wet, slippery environments while doing the lubricating. The chances for food contamination are also lowered. Another advantage of the relubrication-free bearings was greater freedom in designing machinery. Boema didn’t have to ensure access to apply a lubricant, and the client wouldn’t see grease dripping out in an unsanitary fashion.

Field tests confirmed the performance of the bearings

In 2018 Boema tried SKF Food Line ball bearing units, sourcing through Crosa to ensure a trouble-free supply. They were used on a client’s peach-processing equipment. Peaches require delicate handling and frequent washings; a field test would show how well the line worked under the stress of real factory conditions.

After the first year, the client was pleased. For verification, Boema supplied line data and field samples to SKF that confirmed the performance of these bearings in operation. In another field test, bearing consumption was reduced by half.

Product test in progress.

Jam processing line.

The Blue Range is fully compliant with food safety regulations

The blue range units have been developed for compliance with food safety regulations – with food grade and corrosion resistant components, using blue materials for optical detectability. Each element has been designed to balance the highest performance and superior hygienic standards considering EHEDG guidelines (*).

Built from the ground up using foodsafe components and hygienic surface design, the units are developed to proactively eliminate contaminant traps and to reduce the spread of bacteria and allergens. The blue range units can be supplied as open units, or completely sealed units with end cover and back seal.

The patented bearing sealing system and exceptional grease performance contribute to achieving extended bearing life and high reliability. Designed for relubrication-free operations, the units are thus able to reduce maintenance needs and its related grease and labour costs. The relubrication-free feature and hygienic design contribute to cleaning water savings, as well as a reduced disposal of grease absorbents This supports an overall preventive versus disposal oriented environmental culture.