Better efficiency and faster installation with push-fit solutions

With over 70 years’ experience in the field of fittings, valves and hoses for food and water treatment, John Guest, part of the RWC Group, is a pioneer in Fluid Technology. Its innovative range of push-fit solutions improve system performance and provide installation and operational efficiency.

From the first food-grade push-fit fitting in the 1980s to the latest pioneering JG PolarClean range of coaxial hose technology for beer cooling, John Guest – part of the RWC Group – is a pioneer in Fluid Technology with over 70 years’ experience in making some of the world’s best-selling fittings, valves and hoses for food and water treatment. We focus, in particular, on the range of push-fit quick connect solutions for food, beverage distribution and water treatment applications.

From the point of entry to the point of use to the connections within the equipment, these solutions improve system performance and provide installation and operational efficiency without compromising quality or integrity. John Guest’s range is suitable for a variety of applications: water dispensers and chillers, hot brew equipment, beverage vending machines, ice cream machines and beer tapping systems. In addition, in terms of water treatment for both domestic and commercial buildings, it is ideal for softening, refrigeration, filtration, osmosis, cleaning, sanitization and more.

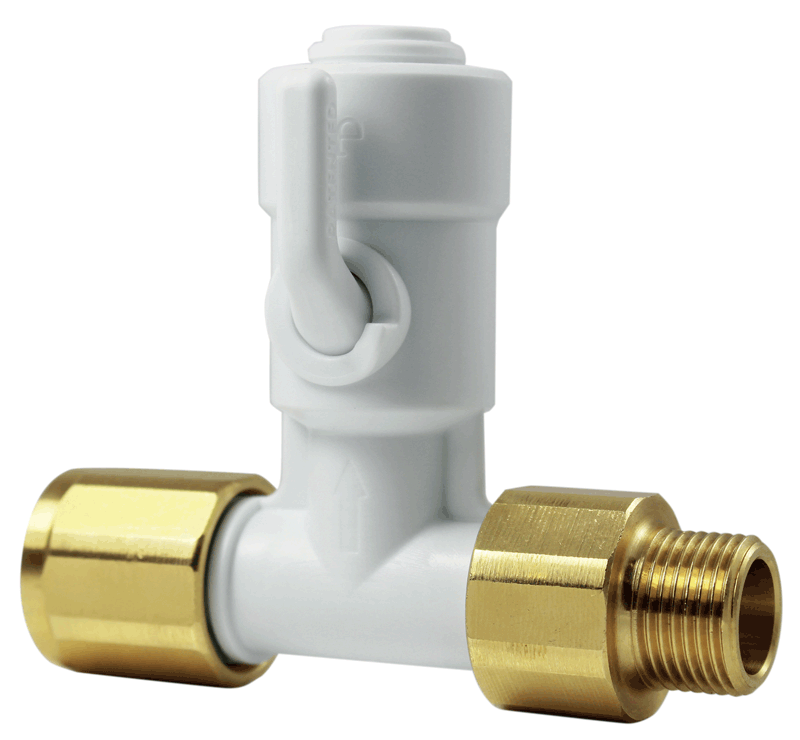

T-series shut-off valves from John Guest, made of Acetal Resin with EPDM O-rings, suitable wfor use with potable water, are highly resistant, corrosion and contamination proof.

PP-series Polyopropylene shut-off valves. Polypropylene has the advantage of being chemically stronger than acetal resin. These valves are suitable for use with drinking water.

A range of shut-off valves suitable for use with potable water

Product portfolio includes shut-off valves, check valves, LLDPE tubing and various accessories. Shut-off valves are made of Acetal Resin with EPDM O-rings, incorporating a check valve to prevent backflow and a 1/4 turn plastic ball valve with all-in-one lever. Capable of withstanding a water pressure of 12 bar at 20oC and 6 bar at 65oC, the T-shut-off valves are suitable for use with potable water and are the only ones on the market where the lever is in one piece with the ball valve, virtually eliminating the risk of breakage, which is more common in products where the lever is free-standing.

JG PolarClean range of coaxial hose technology for beer cooling, in elbow and flat configurations.

JG PolarClean range of coaxial hose technology for beer cooling, in elbow and flat configurations.

In addition, the product is made entirely of plastic, thus avoiding problems of corrosion, limescale build-up and any risk of lead in the water supply. John Guest’s solutions also include a water installation kit that includes, in addition to the shut-off valve with integrated check valve, a 6.35mm inner diameter food pipe, a ¾ BSP female thread solenoid valve fitting with gasket and an elbow with swivel shank for the solenoid valve fitting. The kit is available with 3/8 “x 3/8” BSP and 3/8 “x 1/2” BSP connections. Thanks to this kit, it is possible to benefit from a watertight push-fit connection, capable of supporting a higher flow rate, and extremely easy installation even in tight spaces without the use of tools, counting on the maximum safety of not polluting the upstream water system. All components have food-grade certification and are therefore non-toxic to food.

PI-series elbow connections are made of Acetal resin.

PI-series elbow connections are made of Acetal resin.

PP-series elbow connection in polypropylene.

Robust pipes for applications with variable pressure and temperature

John Guest’s LLPDE plastic pipes made from Low Density Linear Polyethylene complete the range, meeting the needs of intermittent hot and cold-water applications. Made from a non-contaminating material and compatible with JG Super Speedfit fittings, JG shut-off valves and all standard pipe fittings, JG LLPDE hoses offer a more robust solution than conventional hoses, the raw material is FDA approved and NSF certified, with excellent chemical compatibility, for a wide range of applications with variable pressure and temperature up to 65oC. The most common use cases are water and beverage dispensing systems, water purification, water coolers, ice makers and humidifiers.