Towards Increasingly Sustainable Automation

Festo supports companies in their pursuit of digitisation and increasingly sustainable automation with a range of dedicated products. Among these, the IoT-related energy efficiency modules, which capture and process data from the field, stand out

Sustainability, customisation and digitalisation: Festo has been incorporating these trends into its catalogue solutions development policies for many years now. Sustainability and energy efficiency are closely linked: being efficient means producing more and better, while consuming less. As well as being ethical, this model sets Festo apart from its competitors. From consumers to manufacturers, machine builders and component suppliers: thanks to sustainability, all stakeholders can play an active role in relaunching and strengthening the Industry 4.0 process.

A global approach highlights savings for companies

As Sergio Forneris, Festo’s Product Market Manager, explained, customers increasingly require a way to highlight savings resulting from an investment in sustainable automation. Savings are not easy to identify, so it is worth comparing consumption by making a comparison between energy values before and after technical improvements. Festo’s approach is a global one: “ We start from intelligent design with tools for selecting and sizing products and solutions, which are applied with the correct efficiency criteria defined digitally,” Forneris continued. In this respect, IoT, which allows data to be acquired and processed from the field to optimise modern automation processes, has provided an important assist in understanding how automation in modern factories is behaving from an energy standpoint. “The proposition continues with loss analysis services in the plants, and reaches the consulting and training part provided by Festo CTE, which helps to bring out the value of this approach and make it structural within the company.”

A dedicated offer to improve the overall effectiveness of the installation

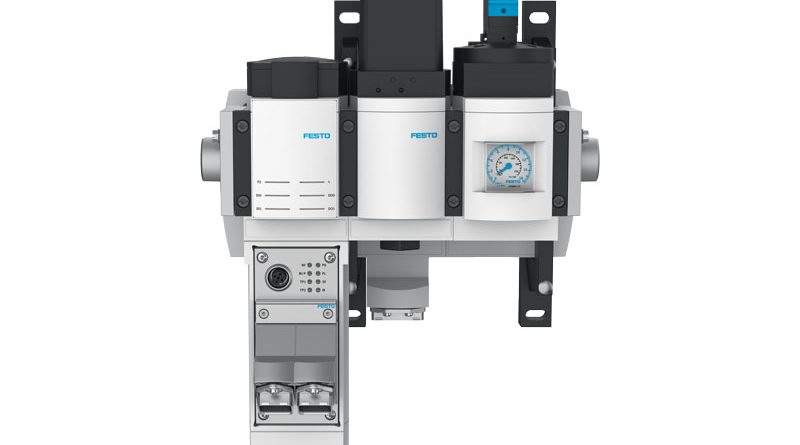

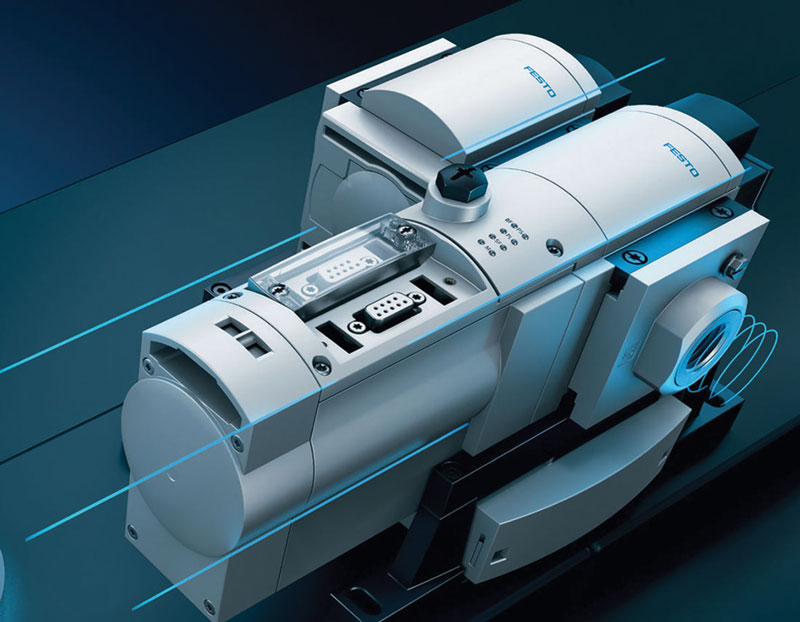

Festo’s offering on the subject of digitisation and sustainability includes a dedicated product basket: Smart Products, which are linked to the IoT world. In addition to fulfilling the technological tasks for the intended use in automation, these solutions acquire and process data from the field. It is therefore possible to improve key parameters for the overall effectiveness of the system (OEE), and to define a virtual model of its behaviour. All this makes it possible to know whether the machine is drifting from an energy point of view. Among Smart Products, the energy efficiency modules MSE6-E2M and MSE6-C2M stand out for their technical features. They are a combination of several elements. In addition to the pressure and flow sensors, the modules are equipped with a 2/2 valve and/or a proportional valve (C2M). Also included are a Fieldbus node for connecting the unit directly to the line PLC, and possible PROFIbus, PROFInet, Ethernet/IP, Ethercat and Modbus/TCP connections.

Real-time data updates regarding energy and process

What makes the MSE6 modules so efficient are their main functions, including the possibility of automatic compressed air shutdown in stand-by mode, as well as automatic recording of pressure, flow and consumption data. These are complemented by the reporting of leaks and abnormal values, and the monitoring of process-relevant data. Besides, with the MSE6-C2M module, the working pressure and stand-by value can be defined via proportional control. With real-time monitoring of the condition of the pneumatic system, operators can access up-to-date energy and process data, as well as comparative data over time. “Values such as flow rate, air consumption and pressure help personnel determine historical trends on consumption, amount of air used per product batch and flow during a malfunction,” Forneris explained. “The MSE6-E2M and C2M modules contribute significantly to improving the consumption of automation machinery and, as a result, meeting environmental targets by lowering and improving the machine’s carbon footprint.” Many other Festo components contribute to improved energy performance, such as SFAM sensors or OVEM vacuum generators. As well as the optimised use of standard components in pneumatic circuits with environmentally friendly solutions.