Digital Transformation on Show

The presentation “The importance of data in digital transformation”, by EFA Automazione, was awarded the title of best contribution in the Smart Manufacturing session at the Industrial Software Forum held on February 6th. The presentation was focused on the key role that data play in OT/IT integration.

by Elena Magistretti

During the first edition of the Industrial Software Forum held on February 6th in Milan on the topic “The evolution of software technologies in Industry 4.0”. EFA Automation obtained an acknowledgement for the best presentation in the “Smart Manufacturing” session. The award was conferred to EFA Automazione for having tackled such a hot topic as the transfer of data to IT systems, illustrating the different protocols available. The integration between OT and IT is a fundamental component for a complete realization of the digital transformation.

At the Forum several case studies were also presented. One of these concerned a manufacturer of the automotive segment who, by means of the analysis of data coming from different production lines, was able to improve product and machine traceability. “Digital transformation – as Franco Andrighetti, founder partner and managing director of EFA Automazione, stated during his presentation – is based on a fundamental element: the datum. With our solutions we can capture data irrespective of where they are found or produced and whatever the device mounted on board the machine, the protocol used, the brand, model and year of installation may be. And, of course, we are also able to transmit them efficiently to the IT systems so that they may be converted into valuable information for the company’s management”.

Effective instruments are needed to collect and select data

Having effective instruments to collect process data generated by factories, production plants or single machines is nowadays an essential aspect for the complete realization of the so-called Digital Transformation. The datum generated by the filed, duly read, filtered and normalized, is the necessary basis to feed the software engine which governs the company, be it a mathematical algorithm (Artificial Intelligence, Machine Learning, etc.) or a more traditional type of algorithm for the management and reporting of production.

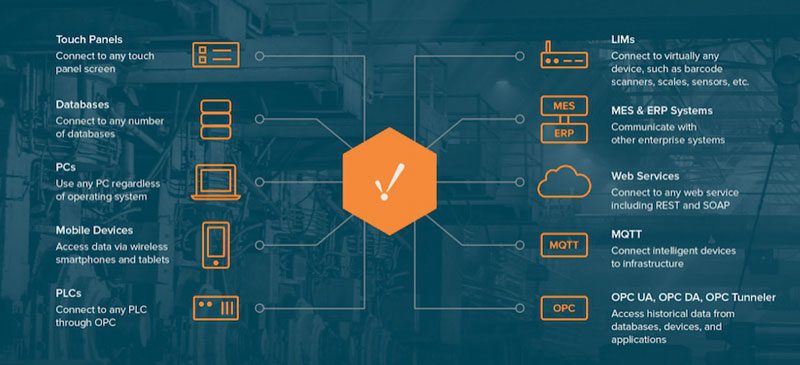

The greatest obstacle which companies may tackle is the huge promiscuity of devices which provide data and, as a consequence, the variety of the communication protocols upon which they are based. Many think that the standardization we witnessed during the past few years in the industrial domain may simplify and speed up the implementation of multi-vendor applications, but in the digital transformation processes which companies end up following this is almost always not the case. EFA Automazione’s product portfolio includes instruments and products specifically designed to enable data collection, whichever device they come from and in whichever format they are provided. The company’s mission is to help companies pursue a fast and economic implementation of Digital Transformation, that is, to create optimal conditions for them to take advantage of the all-round effectiveness of new 4.0 models. How? By guiding them in the choice and use of the best technologies which, having appeared and having been consolidated in the information technology world, are now changing the aspect of industrial automation.

A product and solution range in the software domain

EFA Automazione is also emerging in the software domain by means of the Ignition platform, a Scada/MES architecture developed by Inductive Automation which, on account of its properties of openness and flexibility, is establishing itself on the industrial software scene.

Thanks to Ignition and to the many connectivity solutions (both hardware and software) which the company has been distributing and supporting in Italy for years, EFA now can provide the market with a flexible and innovative integration concept based on the IIoT model. Ignition provides all the advantages of an integrated Scada, HMI and MES platform, a single environment which, besides managing the supervisory control of the plants, enables the use of advanced functions to control and optimize the efficiency of the plants by calculating indices such as, for example, OEE (Overall Equipment Effectiveness). Its open architecture, scalable and web-based (it uses Java and SQL data bases) as well as its compatibility with all operating systems, turns Ignition into a practically universal instrument which may be used in any mode. Its performances in terms of data collection and data analysis with calculation of the OEE and TEEP (Total Effective Equipment Performance) indices, on-the-go access to data and unlimited licences lead Ignition to be a product with an incredible potential not just for system integrators, but also for end users, who will be able to derive the utmost advantage in terms of IoT communication thanks to the native support of the REST and MQTT protocols. At the Forum specific demos were presented allowing visitors to see first-hand the potential of the Ignition software and of all the main connectivity solutions which are part of the product portfolio distributed in Italy.