A richer calculation software thanks to new features

KISSsoft 2021, the latest release of KISSsoft’s calculation software includes a number of innovations concerning new calculation functions for bearings, shafts and crossed helical gears. Manufacturability and reliability assessment and strength calculation have also received due attention. A trial version is available.

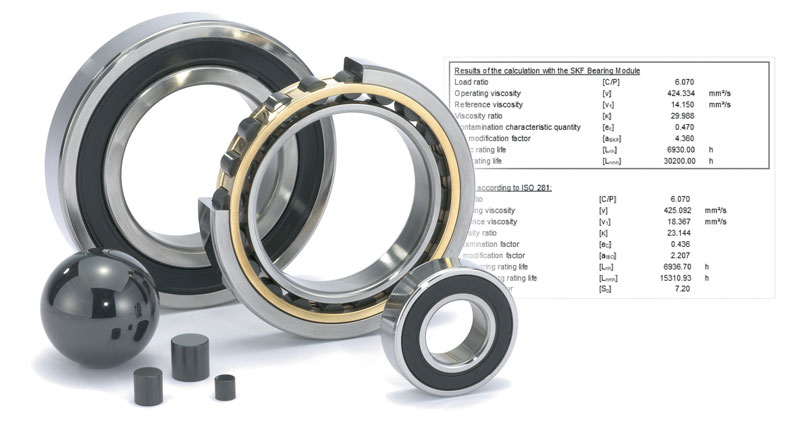

New features concerning bearing calculation are among the highlights of KISSsoft 2021. A connection to the “SKF Cloud” solution enables the input data from KISSsoft/KISSsys to be passed on to the SKF program for calculation. There, the individual rolling bearing is calculated on the basis of the input data. The results, including the stiffness matrix and service life values, can then be transferred to KISSsoft. In KISSsoft, a more precise calculation of the shaft deflection can be carried out using the refined data obtained from the SKF Cloud. As far as shaft calculation is concerned, the revised 7th edition of the FKM Guideline (2020) contains a number of innovations. They include a protective layer factor for galvanized steels, a new material group “Austempered Ductile Iron (ADI)” and a cross-section of the shaft with hub seat (aligned with DIN 743). All material properties have also been adapted. The FKM guideline is thus state of the art. As for crossed helical gear calculation, a new graphic for specific sliding is available: Also for axis crossing angles S1 90° a representation of the tooth meshing in 2D is now provided. In addition, the 2D representation can now also be made in parallel sections to the center axis plane. The option “Determine form diameter dFf and dFa from tooth form” is now also selectable.

Modification variants and measurement data as modifications

When designing and optimizing modifications, often different proposals are compared with each other.

To make it easy to manage the data for these comparisons, different modifications can be grouped in KISSsoft – they then form a variant or set and can be picked individually for a calculation. In this way, for example, the results from the contact analysis can be compared with each other in order to choose the best variant from them. When designing and optimizing modifications, often different proposals are compared with each other. To make it easy to manage the data for these comparisons, different modifications can be grouped in KISSsoft – they then form a variant or set and can be picked individually for a calculation.

In this way, for example, the results from the contact analysis can be compared with each other in order to choose the best variant from them.

Manufacturability assessment

In KISSsoft, you can determine the manufacturability of gears for processes such as power skiving. A collision check ensures that the tool is adapted to the space conditions and does not collide anywhere. In addition to power skiving, this option has now also been implemented for the honing process.

Moreover, a file can be written as an interface to the power skiving manufacturability calculation, which can then be opened and further analyzed with the special program “Power Skiving” from Gleason.

Import option for measurement data

CMM data from a tactile measurement can now be imported directly into KISSsoft and converted for a topological modification. The user can then examine the effect of the manufacturing deviations on the gear properties, such as transmission errors, contact stress, etc.

This function is an essential part of the “closed loop” for optimizing gear design considering manufacturing deviations. The measurement data is linked to the calculation software so that any corrective measures can be quickly investigated and implemented.

System reliability at a glance

In KISSsys, it is possible to calculate the reliability of a system and display it in a graphic. Of course, the reliability of individual gears, shafts and bearing elements can also be displayed in KISSsoft. In addition to the Bertsche and VDMA 23904 methods, KISSsoft and KISSsys now also include the calculation according to AGMA 6006-B20.

Strength calculation

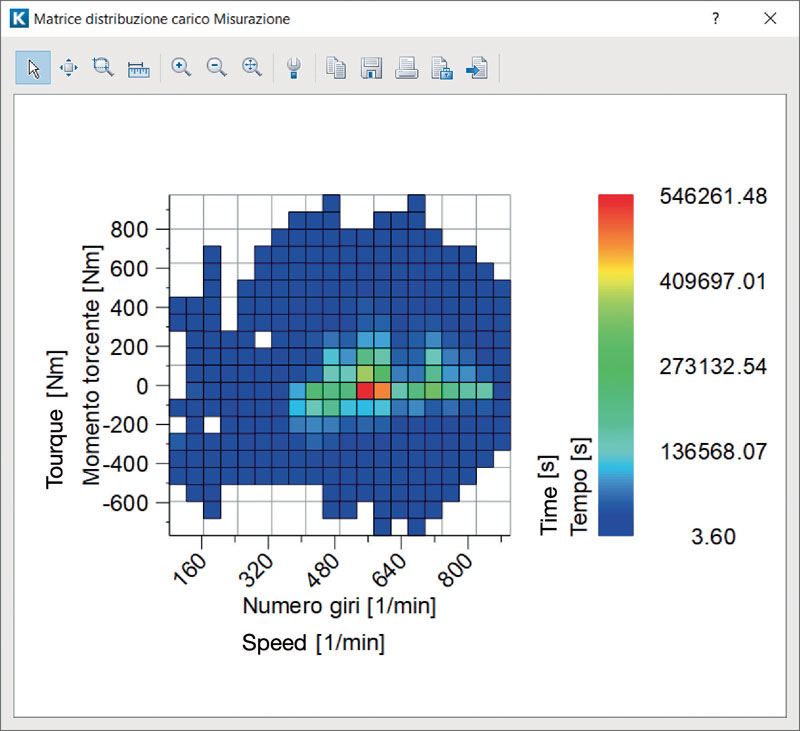

For time series with positive and negative torques, the “Rainflow” method is used to determine a load spectrum with alternating bending factors.In addition to the detailed reports, graphs of the torque curve and frequency distribution in the torque-speed range are now available.

The calculation according to DNV-GL-0036 now also includes the calculation of scuffing safety.