Paperless Calibration to Optimise Costs and Processes

Digitally based and integrated calibration systems reduce the time for preparing documentation, to the benefit of the entire operational process. As shown by the solutions of Beamex, a Finnish company represented in Italy by Danetech

In any industry, the calibration of measuring instruments plays a fundamental role in day-to-day maintenance, both in industries conforming to ISO9000 quality standards and in industries governed by strict international systems, such as pharmaceuticals. But that is not all: thanks to the development of increasingly high-performance measuring instruments and the growing demand for calibrations by control bodies, the number of checks and the resulting documentation has seen a considerable increase (work orders, calibration reports, deadlines, statistics and so on).

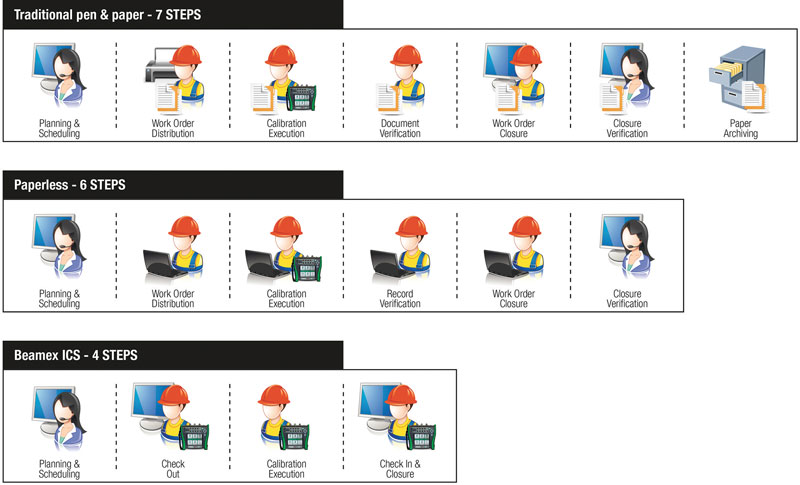

Often, the workload of producing the paperwork for a single calibration process is much greater than the calibration itself, making it one of the largest business costs. The solution to these problems is offered by paperless calibration systems.

By digitising data, the entire operational process is simplified

The development of digitally based and integrated calibration systems enables a drastic reduction in the time needed to prepare paperwork, before and after the actual calibration activity. This is beneficial to the entire operational flow and process, in terms of speed and simplicity of execution, as well as in terms of the quality of the final result, always ensuring compliance with the required reference standards.

Of course, digitalisation of calibration data makes it possible to reduce (if not totally eliminate) the use of paper, radically simplifying the archiving and subsequent research phases, as well as guaranteeing a truly green process.

A scalable and expandable solution created to meet specific requirements

To obtain the benefits described above, an integrated management system can be set up whether the instrument calibration activities are carried out in-house or with the support of external companies. Specialising in calibration systems for pressure, temperature, electrical signals and humidity, Danetech offers integrated solutions based on hardware (portable or laboratory instruments) and software dedicated to calibration, also on cloud platforms. Since 2009, the company has been the Italian representative of Beamex, a Finnish company with extensive experience in the production of calibration instruments, systems and software. In this context, ICS (Integrated Calibration Solution) is a set of hardware and software solutions specifically dedicated to the calibration of measuring instruments. It enables the creation of a digitalised calibration system modelled around the user’s requirements, thanks to a totally scalable structure which can be expanded over time.

Workflow of a calibration process from ‘pen-and-paper’ to integrated system.

Beamex CENTRiCAL mobile calibration benches and carts

You can choose between two softwares, and manage activities even remotely

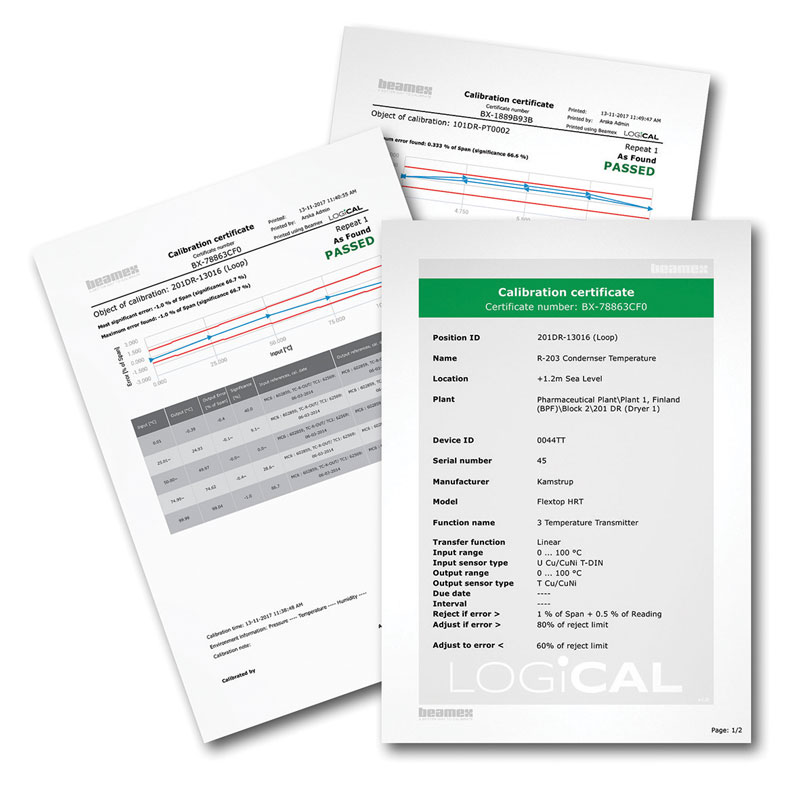

Beamex offers two software solutions, either for direct installation in company networks or on a cloud platform. Beamex CMX and Beamex LOGiCAL both allow the management of: scalable and customisable plant structures and hierarchies; records of measuring instruments to be kept under calibration control, with definition of verification intervals, test execution methods, maximum acceptable tolerance levels, with extensive descriptive and customisation possibilities; records of sample instruments to be used for performing calibrations; schedules; work orders; customisable calibration certificates; historical records of results; trend analysis of instrument performance; extensive search capabilities for particularly numerous instrument records; interfaceability to Beamex calibrators and tablets. Particularly, in addition to providing operational functionalities typical of regulated industries (data integrity, protocol validation and more), the Beamex CMX software can also be integrated into maintenance CMMS/ERPs, allowing fully integrated workflow management. Thanks to its cloud feature, Beamex LOGiCAL software enables the management of activities from any location, a feature which is highly appreciated by service companies.

Calibrators to manage activities both in the field and in the workshop or laboratory

The Beamex offering includes both portable and multifunctional calibration instruments for laboratories as well as electro-instrumental workshops. All multifunctional calibrators of the MC series guarantee direct interfacing to CMX and LOGiCAL software,

as well as complete documentation capabilities for calibration results.

Thanks to bi-directional communication with the software, Beamex calibrators can be programmed with detailed calibration procedures which fully guide the operator through the various stages of the task. Test results are recorded automatically and in paperless form for subsequent transfer to the software for analysis and filing. All this is done without the need for manual transcription, mathematical error calculations and without the need for any paperwork, before and after the calibration phase. Beamex CENTRiCAL mobile calibration trolleys and calibration workstation offer the same capability and integrability of the calibration process, even for activities to be carried out in laboratories or electro-instrument workshops.