The Key Role of IIoT in the Digital Transformation of Businesses

In 2020, the value of the IoT market was €6 billion, slightly down compared to the previous year; there are 93 million connected objects. On the other hand, Industrial IoT is growing: projects are underway in 68% of large companies, only 29% among SMEs, but the gap is narrowing. Smart Factory (66%) and Smart Logistics (27%) are among the most widespread applications, but projects are also emerging in the field of PLM (Smart Lifecycle, 7%). These are the results of the research of the Internet of Things survey of the School of Management of the Politecnico di Milano, presented in April.

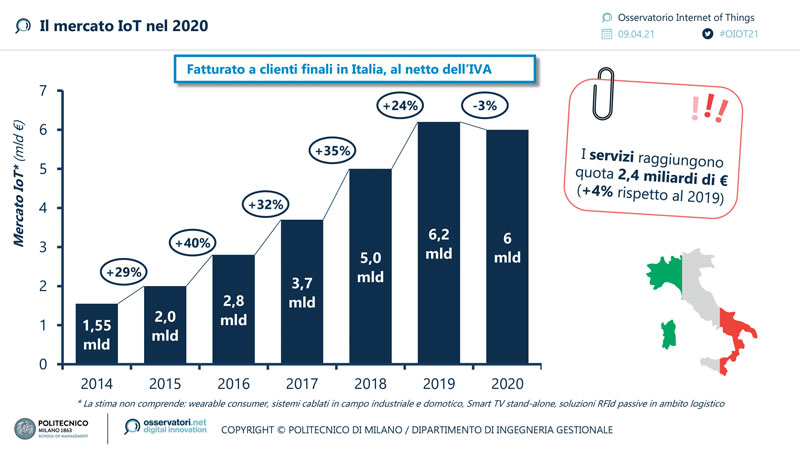

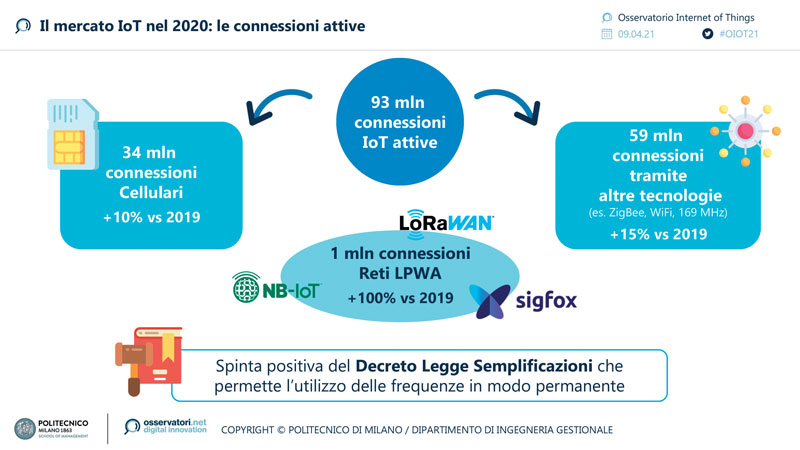

Last April 9, during an online conference entitled “Internet of Things at the test of facts: the value is there, and you can see it!”, the results of the survey carried out by the Internet of Things Osservatorio of the School of Management of Politecnico di Milano were presented. The Covid19 emergency has slowed the growth of the Internet of Things, which had been very rapid in recent years, but the Italian market has withstood the impact of the pandemic, marking only a drop of 3%, in line with the trend recorded in the main western countries (which fluctuates between -5% and +8%), and settling at a value of 6 billion euros. Spending is split evenly between applications that leverage “traditional” cellular connectivity (3 billion, -6%) and those that use other communication technologies (3 billion, stable compared to 2019). There are 93 million active IoT connections in Italy, including 34 million cellular connections (+10%) and 59 million enabled by other technologies (+15%). Among these, Low Power Wide Area (LPWA) networks stand out, reaching for the first time one million connections (+100%). A strong push also comes from the component of services related to connected objects, with a value of 2.4 billion euros and a growth of 4%, in contrast to the general trend of the market. The sector with the most significant growth is Smart Agriculture (€140 million, +17%), driven by solutions for the monitoring and control of agricultural vehicles and equipment, related machinery and robots for field activities. Smart solutions for the factory (€385 million, +10%) and Smart Logistics (€610 million, +4%) are also growing.

The benefits of the Industrial Internet of Things

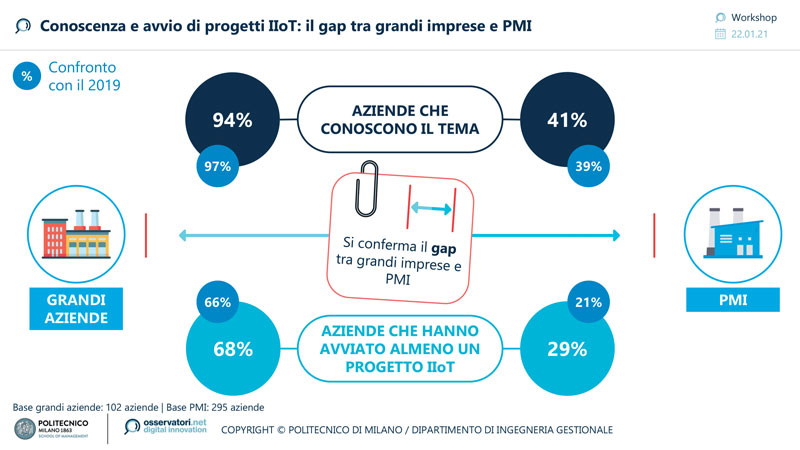

Companies that make use of smart devices succeed on optmizing their systems and processes. In manufacturing processes, for example, the data coming from connected machinery (Smart Factory) allow maintenance activities to be better managed, anticipating malfunctions, instead of correcting them, and reducing time and costs related to machinery downtime. Industrial IoT is growing and the gap between large companies and SMEs is narrowing in terms of awareness and propensity to innovate in a 4.0 perspective. As emerges from a survey conducted by the Observatory on a sample of 102 large companies and 295 Italian SMEs, 94% of large companies are aware of IoT solutions for Industry 4.0 and 68% of them have started at least one project, while among SMEs only 41% have heard of them and just 29% have activated initiatives. However, in 2020, the gap decreased by 5% in terms of knowledge and 6% in terms of projects being activated.

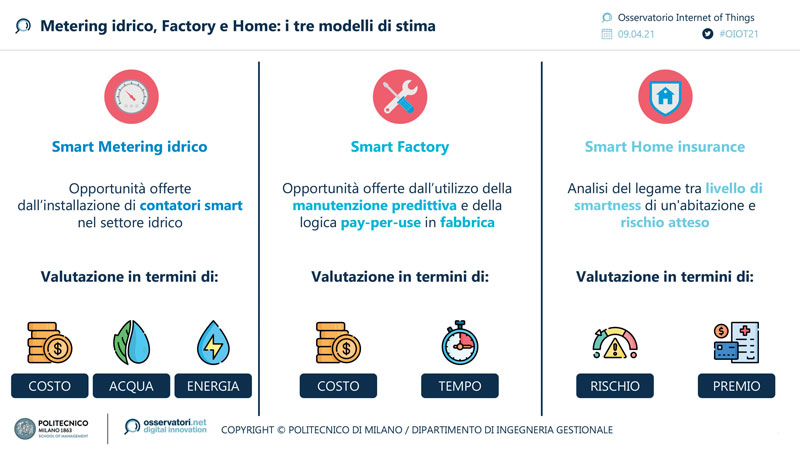

The most popular applications are related to factory management (Smart Factory, 66%), especially for real-time control of production and energy consumption, followed by those supporting logistics (Smart Logistics 27%), driven by the traceability of goods in the warehouse or along the supply chain, and Smart Lifecycle (7%), with projects to improve the development of new models and product upgrades. The emergency has led companies to revise their priorities in terms of new projects and investments. In 2020, only 15% of SMEs and 12% of large companies considered it a priority to activate I-IoT initiatives, compared to 25% and 16%, respectively, who put them on the back burner. 22% of large companies have increased the budget dedicated to IoT projects for Industry 4.0 (14% have reduced it), compared to only 11% of SMEs (12% have decreased it), while a quarter of large companies and a third of SMEs have postponed the decision to the coming months. “The emergency has brought uncertainty among companies but has not stopped the growth of the IoT Industry – said Giovanni Miragliotta, Scientific Director of the Internet of Things Observatory -. The market is gradually shifting from the sale of hardware alone to the sale of additional services, with three out of four companies launching such projects, including information services (84%, such as push notifications in the event of an adverse event), and energy management services (45%). The possibility of activating these services depends on the ability to analyse, manage and exploit the data collected by plants and related machinery, which, however, is still scarce both in large companies (only 38% use the data) and in SMEs (39%), due to scarce skills and financial resources and the difficulty of technological integration”.

Internet of Things enabling Technologies

Low Power Wide Area (LPWA) technologies are driving the technological evolution of the IoT world. “These technologies in non-licensed bandwidth are increasingly adopted for the development of IoT solutions, by virtue of a technological maturity that is consolidating and is now also recognized by regulatory bodies at a national level,” explained Antonio Capone, Scientific Director of the Internet of Things Observatory. Work also continues on defining the technical specifications of 5G by the 3rd Generation Partnership Project (3GPP), the consortium that oversees the standardization of cellular technologies, particularly with regard to the introduction of support for safety critical and industrial applications. The activity of the consortium has been slowed down by the emergency and the roadmap has been revised. It will be necessary to wait at least a year from the release of the technical specifications, initially scheduled for June 2020 and postponed to 2021 for the launch of commercial products.

About the author: Giovanni Miragliotta is Scientific Director of the IoT Observatory of Politecnico di Milano.