State-of-art Hydraulic Control for the Test Stand

Bosch Rexroth and Test Industry-Bimal started a collaboration for a project related to test stands for fluidic parts. Bosch Rexroth A4VBO pump application with new H5SE electronic control, characterized by great scope for control and parameterization, represented the perfect add-on for this project.

Test Industry-Bimal turned to Bosch Rexroth and its A4VBO pump application with new H5SE electronic control for the development of a new test stand for fluidic components. The aim was to develop a pump capable of handling flow rate and pressure but with a high level of accuracy, stability, repeatability and reliability. Bimal, a brand of Test Industry S.r.l. began working in the field of testing in 1984, dedicating itself to designing and manufacturing test stands for fluidic and mechanical parts in the following sectors: hydraulics, mechanics & automotive and aerospace. Test Industry S.r.l. was formally established in 2020 through a merger of Bimal and Leonardo of Brescia, the latter already well-known in the field of testing. Its main mission is to become a unique group and benchmark in the area of test stand production. Its thirty years of experience make the Bimal brand a point of reference in the testing sector, having produced over 1000 test stands, delivered to customers located in more than 30 countries.

The ideal integration in the test stand project

Test stands for fluidic components require flexible, high-performance hydraulic supply systems (to control flow rate and pressure), in order to be able to produce and simulate the various load and operating conditions for the parts tested. The purpose of the test stand is to carry out characterization tests on hydraulic pumps and/or motors, reducing flow rate and pressure as required by the operator. Test Industry-Bimal’s requirement was a pump capable of managing flow rate and pressure simultaneously, with precision, stability, repeatability and reliability. Test Industry-Bimal’s technical department is always attentive to every technological development. That’s why the Bosch Rexroth application for A4VBO pumps with new H5SE electronic control proved to be the most efficient and fastest solution for this project. Test Industry-Bimal’s chooses only the best suppliers, able to contribute added value in the selection of parts, quality, robustness and reliability over time. Bosch Rexroth’s solution, characterized by great scope for control and parameterization, represented the perfect add-on for this project. Bosch Rexroth has committed to proactive provision of support in selecting and putting together the system since cooperation began. But its contribution didn’t end there. It also continued in the commissioning phase, making a suitable expert available to answer to every doubt regarding the parameterization of the system.

Extremely high-level control with Indraworks software

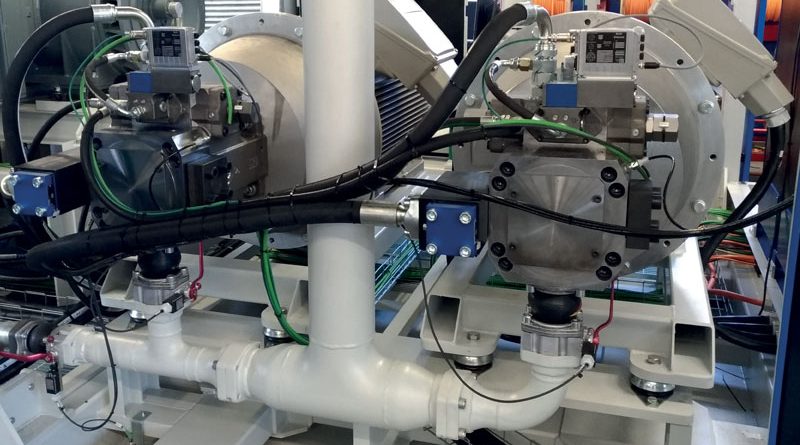

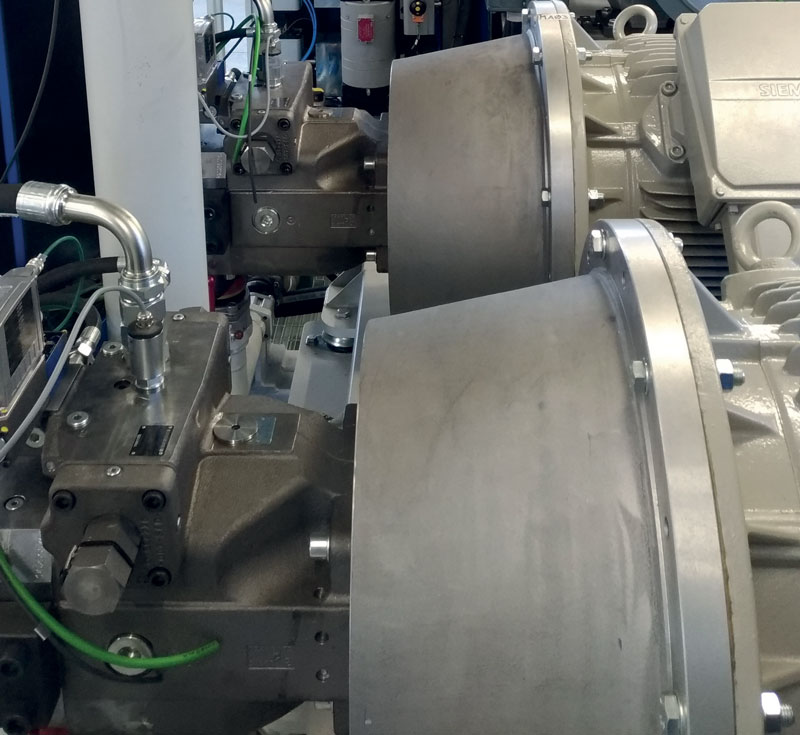

The product in question, the motor and hydraulic pump performance test stand, is custom and has as such been specially made to measure for the end customer, even if it is part of a vast line of similar products also to be found in the catalogue. The design phase lasted about 3 months, during which Test Industry-Bimal technicians took care of all the phases: 3D CAD, issuing drawings, hydraulic and electrical circuit design and software development.

The part has a series of technical characteristics that make it particularly interesting, such as high pressure and high flow rate combined with excellent control stability. The development of the solution and limitation of design times were also greatly facilitated. “Simplifying design, maximizing productivity, optimizing commissioning and minimizing downtime. These are the 4 pillars that will change production, and in Bosch Rexroth the response is Connected Hydraulics: synergy between electronics and hydraulics. Flow rates up to 810 l/m and maximum pressure of 450 bar can be achieved with the A4VBO range, which with the HS5E regulator represents the pinnacle of hydraulic control. The next step will be the introduction of electric motor rotational speed management, to further increase the control of flexibility: the new HS5En control,” said Santo Bivona, Hydrostatic Unit Sales Product Manager. “We hope that the solution will be replicated because it is truly efficient and robust. The level of control that can be parameterized thanks to the Bosch Rexroth Indraworks software supplied with the system is truly amazing. Although tuning a hydraulic plant generally involves many pitfalls, Rexroth has been able to integrate major solutions into Indraworks. All of this, combined with our GEPSO multipurpose software control and automation system, has allowed us to obtain a product that’s unique in its field,” stated Carlo Fasi, Project Engineer at Test Industry – Bimal. l