Fertiliser-proof fittings

In collaboration with the agricultural machine manufacturer Horsch Leeb, Camozzi Automation has developed particularly resistant pneumatic fittings for the braking system of a crop sprayer. In this application, fertilisers pose a challenge to metal components: the 9000 series couplings have passed corrosion tests with urea-based fertilisers with flying colours.

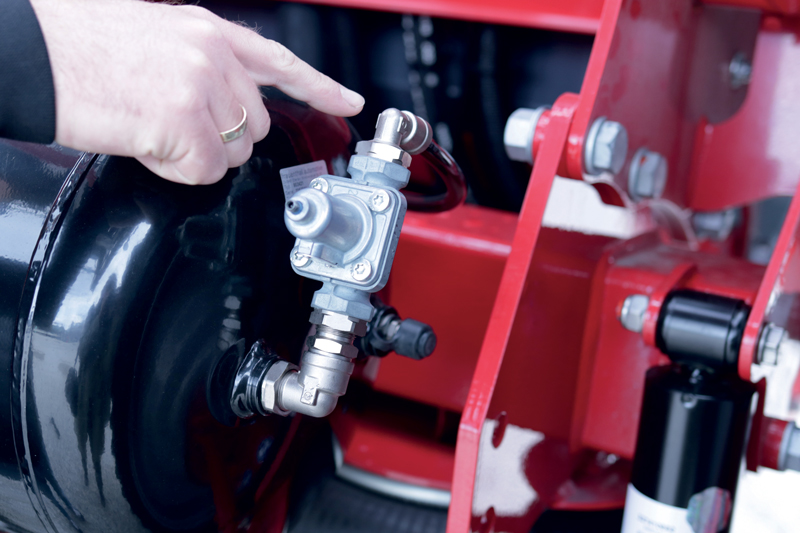

Leeb Application Systems was born in the 60’s in Lower Bavaria. Today Horsch Leeb is a global manufacturer of innovative agricultural technology and modern solutions for soil cultivation, seeding and plant protection. For their new Leeb LT crop sprayers series Horsch Leeb was looking for tube fittings which would be easy to assemble and offer a good resistance against nitrogen fertilizers containing urea. The crop sprayer, through several dozen nozzles, releases a fine spray mist over the plants. Used in windy conditions though the brake system between the wheels is enveloped in a cloud containing urea, putting a strain on the metal components. “In addition to the costly stainless-steel tank said Michael Huber, engineer at Horsch Leeb, the fittings of the airbrake system were also checked for cost improvement potential. Consisting of five separate parts, the old solution was complicated to assemble and susceptible to corrosion. While screening the performance of several fitting types in our lab, we also checked the corrosion resistance against urea in a spray test. The surface of the fittings turned black after exposure to the chemical within a couple of days”.

The solution: compact fittings that makes maintenance easier

Compared to the original fitting, the Camozzi Series 9000 is more compact and can be assembled in only one operation. It is suitable for temperatures between -40°C and 100°C and for pressures up to 16 bar. Sven Schnetzler, Head of Global Business Development at Camozzi Automation’s Transportation division, says: “What makes our patented fitting special is the combination of dirt seal with the release mechanism. With Series 9000 we can remove the tube from the fitting with a special tool, without destroying the integrity of the dirt protection seal. This is a great feature for maintenance and repair”.

A chemical treatment with nickel and phosphor offered the best resistance

Surface treatment was another big challenge in tis application, owing to the aggressive effects of urea. After many trials with different coatings, Camozzi was able to prove that a chemical treatment with nickel and phosphor offered the best resistance against the aggressive effects of urea. A nickel phosphor alloy was applied with a thickness of five microns on top of the surface of the brass fitting. This technique guarantees an even thickness all over the component and excellent resistance to corrosion. The decision against the stainless-steel fittings was made in order to reduce cost. Thanks to a reduced handling, the sprayer manufacturer could save around 20% of the overall costs compared to the previously used components. In addition, the quality of the final product was significantly increased. The LT line of sprayers is now being mass produced. equipped with a relatively smaller tank and therefore attractive to medium-sized and family-run businesses. Horsch Leeb has also decided to fit Camozzi pneumatic cylinders to its machines. For its part, Camozzi will include these particularly acid-resistant fittings in its standard range.