Even More Options for Motion Control in Intralogistics

The expansion in the range of drum motors, now available with larger diameters and much easier to integrate in production systems, as well as new control solutions and the enrichment of the MCP modular transportation platform. These are some of the new products which Interroll presented at Intralogistica 2018, confirming its engagement, in terms of R&D, to support the digitization of production.

by Giorgia Stella

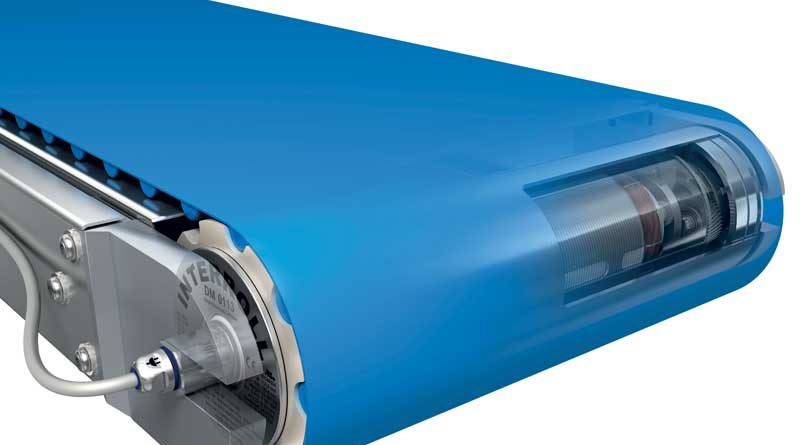

A winning model should not be changed. If anything, the range might be increased. Interroll’s participation in Intralogistica 2018 coincided with the launch in Italy of the latest generation of drum motors, which stands out for a series of important innovations such as stronger axes and bearings providing a longer working life or greater torque values with a very low nise level thanks to the extremely stable epicycloidal gear. “The range of Interroll drum motors was broadened this year with the 113 and 138 diameters”, Claudio Carnino, sales manager and country speaker for Interroll Italia, told us. “Hygiene, ease of maintenance and low consumption are as always fundamental properties of the product”. The new drum motors are really a plug and play solution: unlike the previous generation, power is transmitted by means of a simple plug-in clamp.

Down times for maintenance or repairs are considerably reduced, to the user’s advantage, even from an economic standpoint. With respect to alternative drive systems, these motors show a very low loss in power, which in turn implies a drastic reduction in running costs.

From control solutions to the platform for “deep freeze” environments

The Swiss company’s stand at Intralogistica was also enriched by such control solutions as Multicontrol, a network card for the control and integration of Interroll’s Roller Drive in numerous applications concerning transportation systems, such as, transporters without static pressure, roller curves, forward transporters without subdivision in areas and 45° or 90° unloading areas. Communication in real time using PROFINET, EtherNet/IP or EtherCAT is enabled by a simple setting of each MultiControl unit.

Even the Modular Conveying Platform (MCP), designed to increase the efficiency in transportation of any type of material, is evolving. “This year’s innovation is linked to the so-called ‘deep freeze’, that is, modules and components capable of operating at very low temperatures”, Mr Carnino added.

“This implies that the different elements – from techno-polymers to lubricants for the roller’s bearings – are created purposely to resist at very low temperatures, in environments which present advanced logistics requirements very similar to those of production environments characterised by normal temperatures”.

A positive assessment for the Italian branch

Research evidently moves increasingly moves towards Industry 4.0 for the Interroll Group, whose income in 2017 grew by 7.8%

year-on-year. “Digitization of components – especially, but not only, control boards – is an increasingly relevant aspect, from the design phase. This is a compulsory stage to allow manufacturers of machines and plants to digitize in turn their production”, Claudio Carnino carried on, expressing satisfaction for the moment which Interroll Italia is experiencing. “Our 2017 results were excellent and the beginning of this year confirmed the positive trend. Products launched last year were definitely appreciated by Italian clients, just like our capability of interfacing with the market”.