When OEMs Become Data Scientists

Thanks to smart condition monitoring it is possible to deliver real-time condition monitoring with no additional measurement sensors. Let’s find out with Lenze what are the multiple benefits of this application for OEMs

Topics such as predictive maintenance and predictive models based on artificial intelligence (AI) are currently of great interest in mechanical engineering. But a lot of customers have no real idea of the kind of predictions that can be made. En fact, all they are interested in is monitoring machines and processes. Today, thanks to Lenze technology, it is possible to realize a smart condition monitoring application that provides extensive information about the state of health of machines and plants, without the need for any additional, costly sensor technology.

Differences between condition monitoring and predictive maintenance

Condition monitoring and predictive maintenance are repeatedly treated as being synonymous, but are in fact two very different concepts. Predictive maintenance is the prediction of events, or the probability of possible events. For example, if the probability of a fault occurring in a gearbox within the next 50 operating hours rises to over 90%. This kind of prediction could be very useful, in order to plan the replacement of a gearbox in due time before the machine or plant does in fact break down. On the other hand, condition monitoring is a pre-stage that permits a more detailed description of the current state by interpreting the available data. This requires a deeper understanding of the machines and processes so as to generate meaningful information from the bare data. Analyses based on machine learning and artificial intelligence can help identify anomalies faster.

Information value can be extracted from data sources already available

The fact that the added value offered by condition monitoring is not associated with higher hardware costs makes it particularly interesting for OEMs.This is because no additional sensors are needed, as we have seen. The trick with this solution is to extract the added information value from data sources that are already available. Lenze provides pre-tested algorithms for various applications, and helps mechanical engineers turn their process expertise and knowledge of machines into a condition monitoring model that will improve efficiency.

Example of a 2-axis robot: two different approaches

Let’s now see a concrete example of a 2-axis robot, to better understand the potential of this application. Lenze demonstrates this principle with two different approaches to condition monitoring. One of these is model-based, where the actual values that are measured are compared with those from the assumed mathematical description of the machine. If certain tolerances are exceeded, this is interpreted as a fault. The second approach is data-based. An algorithm learns the system’s behavior and the reciprocal influences of various parameters, for example velocity, acceleration, torque, position and current consumption. The real values are compared with the learned description so as to define deviations. Thanks to the machine-module created by Lenze, it is possible to simulate issues such as increased friction on the spindle and wear on the belt drive. The anomalies can be detected in both cases through current and torque values, be this through an absolute increase in the value or through anomalies in the frequency analysis. Condition monitoring raises the alarm in both cases and shows the causes on a dashboard.

Complete freedom of choice: control system or cloud?

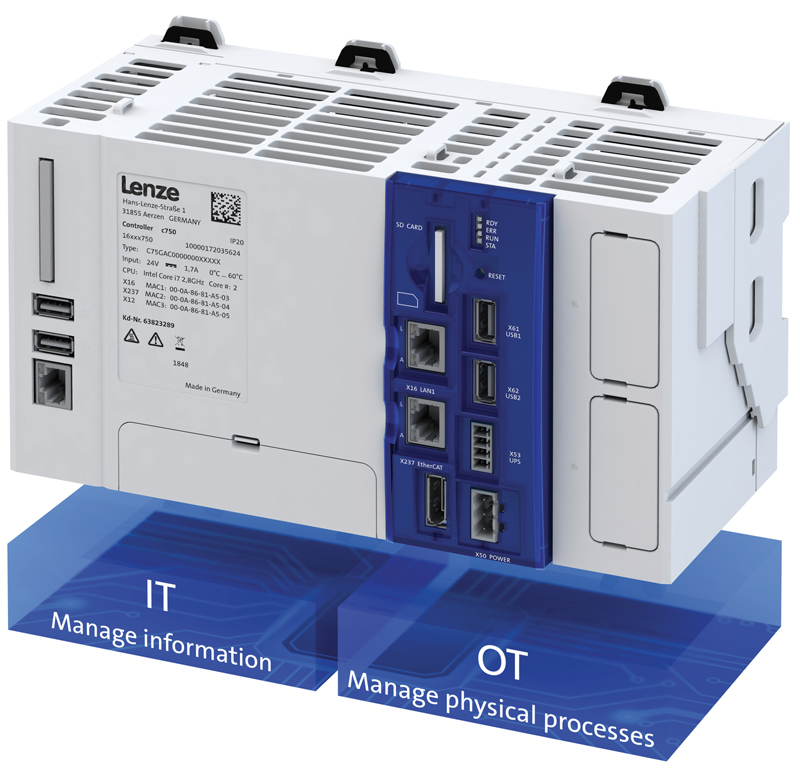

The two condition monitoring approaches differ not only in terms of their concept. The question as to how this data is evaluated also has different answers. The model-based evaluation usually takes place on the control system because it does not require any significant computing power. ML and AI analyses used for data-based evaluations are normally implemented as a cloud application. Lenze’s portfolio gives the OEM complete freedom of choice. This includes a number of different three-dimensional PLCs for model-based condition monitoring. Data-based evaluation can also be carried out locally if the powerful c750 cabinet controller is used. Alternatively, a route to the cloud can be provided using the x500 gateway. Combined with the x4 platform, mechanical engineers have a turnkey cloud solution that covers not only condition monitoring, but also remote maintenance for the machine and user-friendly asset management.

Conclusion

Efficient condition monitoring is based on the interpretation of existing information. No additional sensor technology is needed. Instead, the machine’s devices work as sensors. With its extensive automation portfolio (that contains hardware, software, networks and cloud applications) and the expertise it has gained in this field, Lenze is able to offer comprehensive support when it comes to interpreting data. At the same time, the manufacturer helps OEMs become data scientists for their machines.