High-performance solenoids for earth moving machines

The synergy between ATAM and Italmagneti, which today form the ATAM Group, has led to the production of a new family of solenoids for proportional valves used in the hydraulic circuits of earthmoving machinery. These high-performance components are capable of operating at pressures of up to 450 bar and have been tested for 10 million cycles.

The technical/commercial collaboration between ATAM, a specialist in the field of encapsulated coils and industrial connections, and ITALMAGNETI, a specialist in the production of electromagnetic tubes for the control of solenoid valves and linear actuators, has led to the production of a new range of advanced solenoids for hydraulic applications. Today the two companies operate collectively as the ATAM Group.

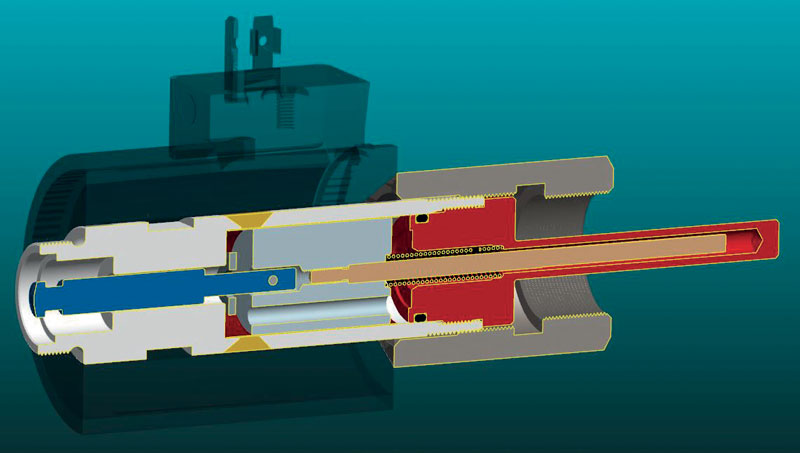

Tailored solenoids for the hydraulic circuits of earth moving equipment

The solenoid for proportional valves, consisting of a perfectly integrated ATAM coil and ITALMAGNETI linear actuator, is mainly used in the hydraulic circuits of agricultural machinery, earth-moving machinery, compactors and machines for urban cleaning, forklifts and concrete mixers and the like. It facilitates, for example, the movement of the arm on a bulldozer or the rotation of a concrete mixer, by regulating the flow of oil and directing it where and when it is necessary, by precisely maintaining the required pressure and flow rate. Recently, ATAM and ITALMAGNETI have developed a family of solenoids for use with proportional valves for several applications dedicated to earthmoving. These high-performance products are capable of operating with pressures of the order of 450 bar, where classic hydraulics reaches only 250 bar, and are tested for 10 million cycles, compared to approximately 1 million cycles of the traditional components.

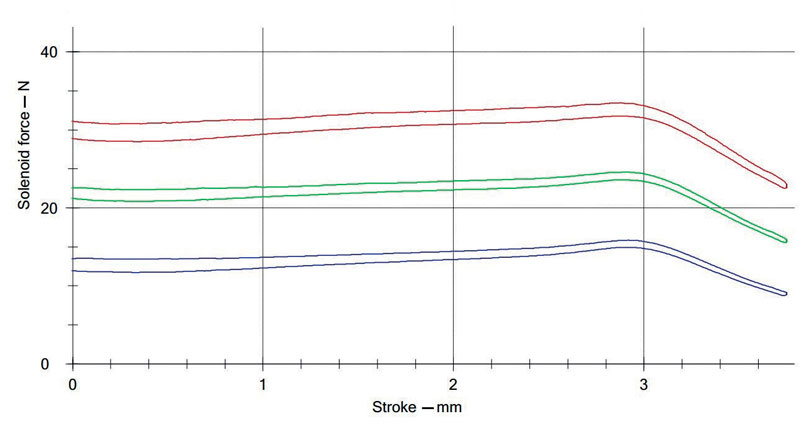

Low hysteresis values enable precise control of the solenoid valve

Each solenoid is distinguished by the linear actuator which allows particularly low hysteresis values: this enables a very precise control of the solenoid valve, both with an increase and decrease in pressure. In order to achieve very low hysteresis values, special finishes have been applied to the internal components of the actuator to achieve very low roughness (0.1 – 0.15μm); in addition an anti-friction foil has been placed between the internal wall of the actuator and the mobile core to optimize the sliding of the latter. Finally, the coil features an IP69K degree of protection; it is supplied with all the most common electrical connections on the market and is encapsulated in various resins to ensure the most suitable insulation class.

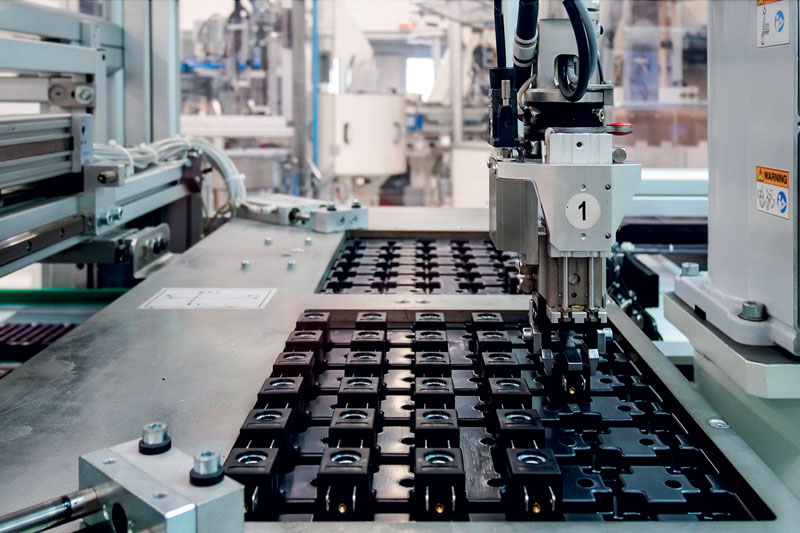

ATAM Group can produce solutions with a high technical content, taking the customer’s outline specification and devising an outcome where the solenoid integrates perfectly into the components already in use. The Group also excels with its high level of production flexibility, with the ability to manage small scale production through to large batches on automated lines.