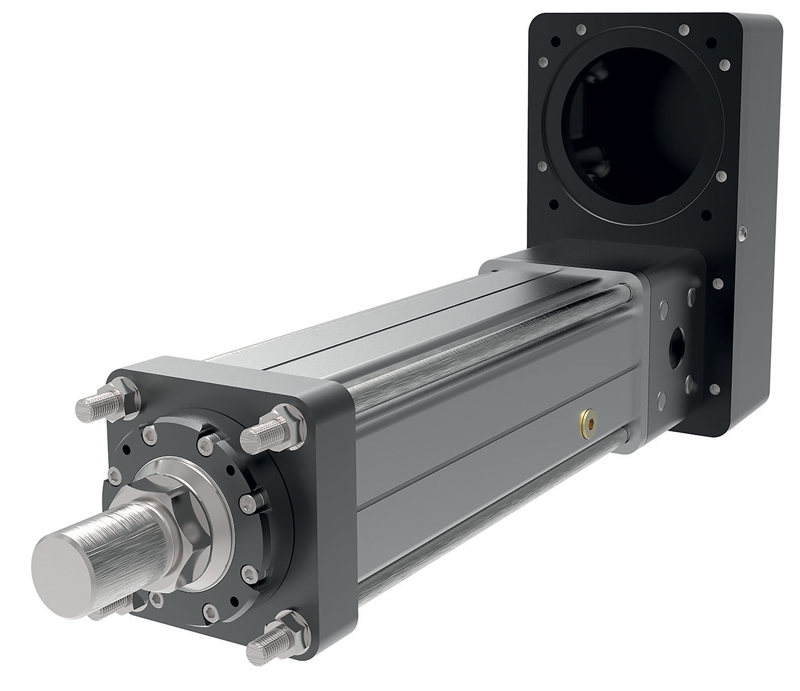

Reliability and power in a compact design

The GTX Exlar® series of linear actuators, distributed exclusively in Italy by Servotecnica, has been developed following a new manufacturing philosophy. The three smallest sizes of the GSX series have been revised while maintaining high performance and standardising the number of options, so that delivery times have been significantly accelerated. Currently the GTX series is available with metric threads to facilitate integration into European market applications.

Headquartered in the USA and acquired by Curtiss Wright Corporation, Exlar® is a historical partner for Servotecnica, the exclusive distributor of its products on the Italian market which focuses its core business on the production of linear actuators. These solutions are distinguished by their geometry, which sets them apart from the majority of actuators on the market. “The traditional configuration of a linear actuator features a screw with a recirculating ball nut and a rotary motor at the end or in parallel,” Lorenzo Protti, Servotecnica’s Product Manager, explained, “ whereas Exlar® linear actuators are built using satellite roller technology. The unique design is represented by the motor-screw assembly where the spindle nut is built into the motor shaft and allows the sliding of the satellite rollers and the consequent translation of the rod.” Thanks to this configuration Exlar® offers a more compact solution with the same force output. Another advantage is the life time of the component: compared to ball bearings, satellite roller technology offers many more contact points between screw and spindle nut. This allows better distribution of force and friction, and consequently the management of more demanding duty cycles. The strength of the design is also based on the construction of actuators used in demanding applications.

The new series: standard options for shorter delivery times

The range of Exlar® actuators consists of five series: GSX, GTX, TTX, FTX and FTP. The GSX series, in particular, consists of five sizes, three of which, the smallest, have been the object of a recent production overhaul which gave rise to the GTX series. Leaving the technology of the reverse satellite roller screw unchanged, only the most popular options have been retained for the benefit of much shorter delivery times. Thanks to its metric threads, the new GTX Exlar® series meets the needs of the European market. The two largest sizes have retained the GSX code and imperial threads. It is also possible to integrate encoders and resolvers of different types and brands into the system.

The other series which make up the family

“The TTX series is a complete system,” Lorenzo Protti continued, “comprising motor, actuator and driver with various fieldbus systems. The other two series, FTX and FTP, consist only of the screw, which can be assembled with any motor, provided that the torque and speed requirements are met. By opting for a solution with an external motor, it is possible to achieve higher forces (up to 351 kN) and strokes (up to 900 mm) compared to the integrated series. Servotecnica is able to modulate the offer by proposing a complete package consisting of actuator, motor and drive.”

Reliability as the customer’s first requirement

Exlar® actuators with satellite roller technology are particularly suitable for use in applications where reliability is the customer’s first requirement and when it is necessary to meet particularly critical conditions including demanding cycle times, extended temperatures and reduced installation space. Target markets include electrical presses, packaging, automotive, Oil & Gas (valve opening and closing) and the defence-aerospace sector.