Metrology enters the factory

Modern applications increasingly require metrology to leave the laboratory and get into the industrial production environment. Activities enabling this process are identified by a new word, “metrotronics”. told us all about it

by Fabio Rosi

In the manufacturing sector, especially in the segment linked to the automotive industry, a remarkable increase in the request for measures carried out directly on the production line has been recorded. For many industrial sectors the need to ensure the conformity of all products to specifications is increasingly felt, and statistical control on a sample basis carried put in the laboratory has therefore become insufficient. On average, it is necessary to measure items automatically, with a frequency of more than a thousand pieces an hour; this measurement may also be associated with “cosmetic” or functional quality control. The accuracy expected of measurements taken on the production line is however increasingly close to the one provided by laboratory instruments, and this requires an ever more stringent metrological approach. On the other hand, the practical application of metrology has always found its natural setting in the laboratory, in a controlled environment; even instruments and technologies designed to carry out measurements have evolved for this environment. Now the need to leave the laboratory implies a remarkable series of activities, which may be seen as a new opportunity for the current metrological segment. Hence the need to identify with a term a series of actions, thoughts, rules and technologies so that these may take up a defined setting and shape. I took the liberty to create the neologism “metrotronics” (presented in April at the convention hosted by INRIM, the National Institute for Metrological Research, on the “metrology of functional surfaces”) to identify all that fall within the domain of the adaptation of metrological tools so that they may operate directly and efficiently in an industrial production environment.

What does “metrotronics” mean?

“Metrotronics” is a word made up of “metro(logy)” and “(mecha)tronics”. “Metrology”, according to the definition provided by VIM, the Intenrational Metrology Dictionary, article 2.2, is the science of measurement and of its applications. “Mechatronics” is a word made up of mecha(nics) and (elect)tronics and it means “science stemming from the integration of mechanics and electronics so as to design, develop and control systems and processes with a high degree of automation and integration” (ref. Treccani online encyclopedia).

Many companies manufacturing measurement tools are investing a sizeable share of their resources in research and development in this very domain.

Automatic measurement in a non-controlled environment

Let us now examine some key aspects of automatic measurement in a non-controlled environment.

Let us start with the impossibility of controlling all aspects which could be controlled in a laboratory environment and which might influence the object being measured; specifically, the influence of non-controlled variables will be more or less critical according to the type of measurement to be carried out. Another very important aspect is linked to the impossibility of controlling everything which could be controlled in the laboratory and which influenced the measurement tool: in this case much depends on the measurement instrument we envisage using.

Let us now consider the difficulty or impossibility of preparing the object which needs to be measured in the optimal and controlled way used to prepare it in the laboratory. The repetitive and fast aspect of the measurement implies its automation. In laboratories there are specialized operators who prepare the object for measurement, a fundamental and complex operation which, if carried out by an automatic mechanism in an inappropriate way, may lead to erroneous measurements.

Let us now deal with the speed of measurement. Measuring an item in a few seconds and hundreds of dimensions per second is often the rule for these machines. A considerable part of measurement instruments cannot carry out the measurement at a sufficient speed. There are two reasons for this: a technological problem linked to the instrument, or a problem linked to the measurement method. Finally, let us consider the need of measuring repeatability and accuracy, possibly in real time. In an industrial environment the loss in accuracy of instruments is on average higher than what happens in a laboratory, therefore it is essential to know the actual repeatability and accuracy of the instrument. Further on a case history illustrating a possible solution will be presented.

A practical example of a micrometric measurement plant

Just considering these key aspects of automatic measurement allows to ficus clearly on a peculiarity of metrotronics: it is a science which includes a weighted evaluation o several metrological aspects and of the combined uncertainties generated by the measurement of different physical dimensions.

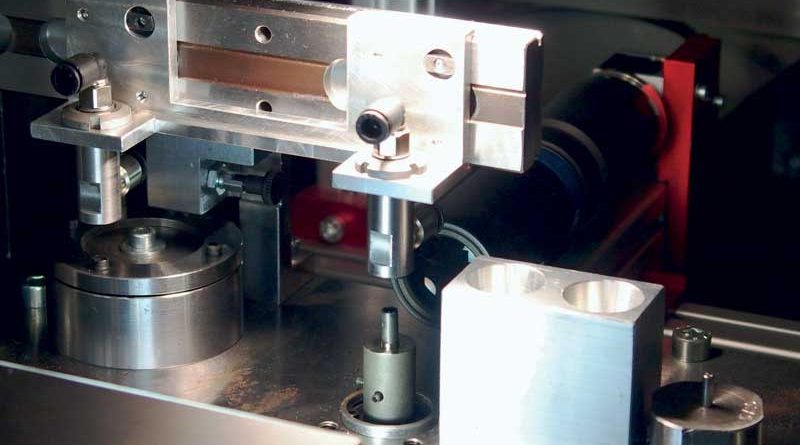

I shall relate the experience of a micrometric measurement plant, recently built by VEA.

The plant, which carries out measurements on the production line of cylindrical objects with a diameter of about 50 mm, measures one item every three seconds and the accuracy requested is 4 µm.

Items come out of a washing machine and are dried with hot air jets: every piston comes out at a different temperature, with excursions of up to 40°C, which imply about 46 µm of thermal expansion.

Improvements to obtain an optimized efficiency

Regarding the thermal aspect, high speed thermal sensors have been made to specification, because the ones available on the market were not fast enough, and a four-stage self-calibrating temperature compensation algorithm was adopted to take into consideration room temperature and the temperature of the item, gauge and optical sensor carrying out the measurement.

In order to detect the loss in accuracy of the instruments, a self-calibrating system was adopted, which contains internally the reference gauges, with an automatic procedure to verify any accuracy variations. Vibrations present in the environment may sometimes cause erroneous measurements. The use of a particular proprietary technology, called MSA (Micro Stabilized Accuracy), allows to reveal in real time the typical deviation of a given measurement. Hence the repeatability of the instrument may be inferred and, if the average deviation is high, it may be decided to repeat the measurement, even because vibrations are often temporary occurrences. In plants under construction the trend is to improve the accuracy of the systems by increasing the interaction among different physical sizes, for instance, by introducing accelerometers or devices allowing to analyse the reflection index of the objects which need to be measured.

A technology with significant scope for improvement

I shall conclude this “introduction” to metrotronics with some thoughts which would require further analysis.

The quantity of information generated by measurement systems on the production line allows to improve the production process automatically, by means of an adequate retroaction system. Besides, these technologies are fully entitled to the new grants envisaged by the national Industry 4.0 strategic plan, which could represent a good opportunity for many companies.

Even though there are many measurement instruments in production lines, these are still for the best part manual solutions or systems which, when automated, often enough do not consider environmental factors, nor some of the aspects discussed in this article; this means that there is still ample room for improvement. Paraphrasing a famous saying, I could state that “behind a great metrotronic there is always a great metrologist”, because the two professions are highly complementary: the metrologist has the knowledge which allows to identify the uncertainties; the metrotronic has the knowledge it takes to find out solutions for the uncertainties which have been identified.

Author: Fabio Rosi is responsible for research and development at VEA