Motion Control for Aseptic Filling

Motion control specialist Yaskawa supported a client in the restyling of a multi-format rotary washing machine, for vials and bottles for aseptic production. The hallenge was to move from a mechanical to an electronic concept

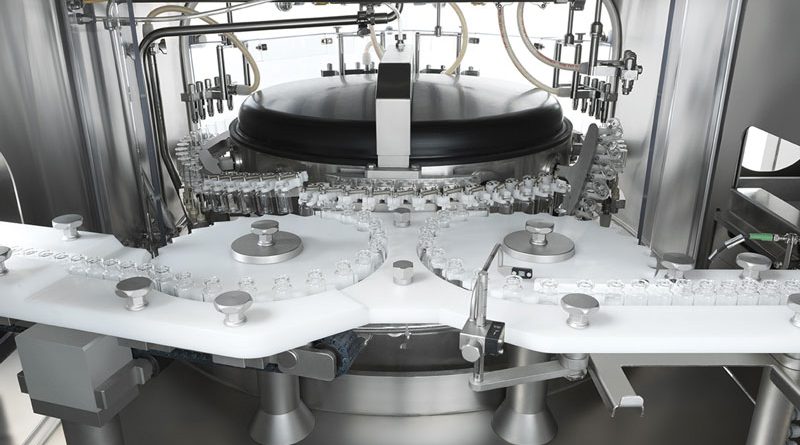

Located right at the heart of the Packaging Valley, the cluster of advanced mechanics and industrial automation in Emilia Romagna, IMA has been designing and manufacturing hi-tech automatic machines for the processing and packaging of pharmaceuticals, cosmetics, food, tea and coffee for almost sixty years. The company philosophy, based on research and innovation, considers the constant technological upgrading of machines and plants to be of primary importance, in order to pursue a continuous evolution of efficiency and sustainability of its production lines. Recently IMA Life has dedicated itself to the innovation of the standard module of its VEGA Series multi-format rotary washing machines, part of the aseptic filling line for vials and bottles for sterile environments. The restyling has involved the entire series, which has gone from a mechanical concept to a fully electronic one, with the adoption of a hybrid system of engines.

Advanced motion control solutions

IMA wanted to increase the flexibility and scalability of the hardware and software of the machines, thereby reducing their footprint and costs. “Since in the past we had experienced some problems with the mechatronic solutions of a labelling machine, a tray filler with advanced collision detection and a module for loading bottles into a tunnel in quincunx layout, we decided to install advanced motion control solutions for the multi-format rotary washing machines in the IMA Life line”, Maurizio Lodato, HW & SW Technical Dept. Manager at IMA Life, at the Calenzano site, near Florence, explained.

For the ideal solution, the company turned to Yaskawa. For the machine’s basic functionality of transporting bottles and managing the washing trolley, the mechatronic axis control subsystem consists of an MP3300iec machine controller with Sigma-7 motors and drives.

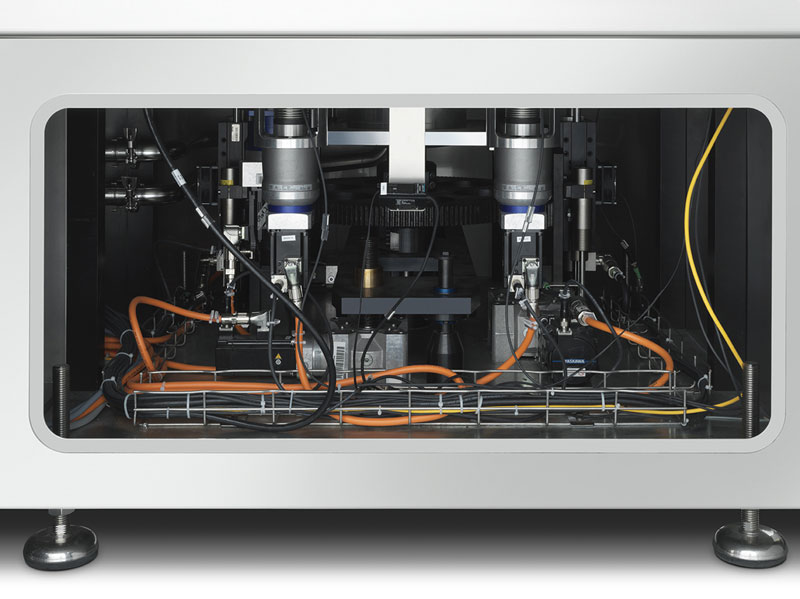

The washing machine’s control panel.

The restyling involved moving from a mechanical to an electronic solution.

A hybrid system of engines has been adopted.

Two important challenges lie ahead

Yaskawa was immediately faced with major challenges. First of all, it had to incorporate a non-digital, non-real-time sub-system into a digital, real-time control system. The restyling of the VEGA series required the use of two special motors for lifting the carousel, which were neither produced by Yaskawa nor equipped with a Yaskawa digital interface, and therefore could not be managed directly by the chosen controller.

Two possible solutions were identified. The first proposed to use a Yaskawa drive “in simulation” mode (that is, without a motor connected to it) to generate the analogue trajectory of the non-Yaskawa external axes. The second solution would have controlled the external system using deterministic trajectory “streaming data” generated by a virtual axis in the Yaskawa controller. IMA opted for the latter option, which offered several advantages: in addition to being strong and reliable, it also reduced components (space in the cabinet) and wiring, while offering a significant cost saving.

A further challenge was that the external two-motor system was equipped with an incremental encoder. As this is a “vertical gantry” mechanical configuration, it was necessary to manage the Homing procedure at the machine start-up, the management and correction of any mechanical mismatch during the normal cycle and in the event of an emergency stop. During the tests to explore the tollerance of the Streaming solution, we tried to overload the CPU of the Yaskawa controller, burdening it with about ten additional virtual axes in electronic cams, some FOR_TO cycles and several additional subroutines. As a result, the CPU did not exceed 60% of its computing capacity, confirming that the CPU’s real-time management and multitasking behaved exactly as expected.

Standard components available worldwide

“Yaskawa helped us to evaluate the most suitable motion control solution for our requirements, supporting us in making the most suitable choice from a hardware, software and functional standpoint, demonstrating great competence and helpfulness,” Maurizio Lodato said. “IMA Life was thus able to analyse and evaluate a series of possible alternatives, and then choose the most efficient and performing one”.

The use of standard components, both hardware and software, with worldwide availability, was another essential factor in the customer’s choice of the Yaskawa solution. “Yaskawa’s motion control system was not only efficient in terms of both hardware and software, but was also designed to ensure the longevity and resilience of the final product due to the predominant use of standard components. In addition, the solution is environmentally sustainable, thanks to its high performance which allows a lower energy impact” Maurizio Lodato concluded.