With Wireless Transducers Goodbye to Old Torque Analyzers

Dalmar presents ZippTork, a dynamic and wireless torque transducer for calibration and clamping control. Tightening torque is easily verifiable via smartphone, tablet and pc, thanks to the free software configurable using ZippTork, together with the collected and stored data.

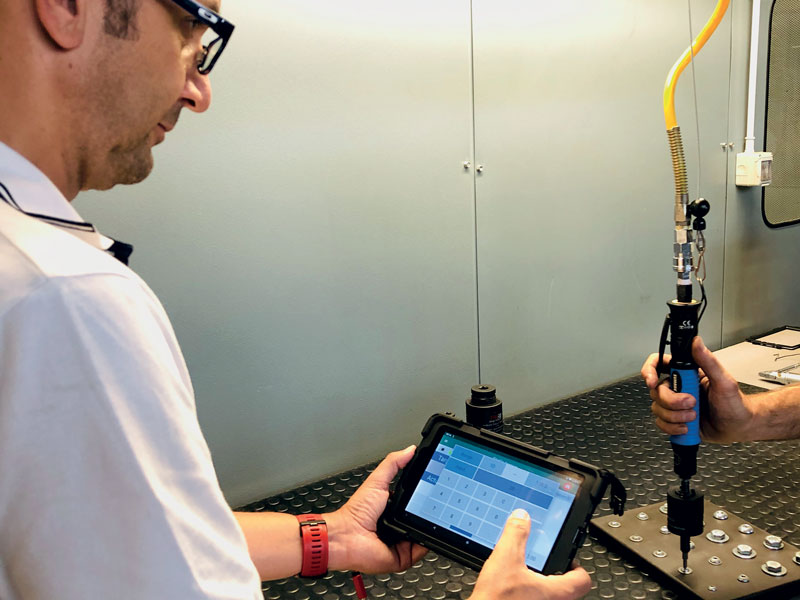

ZippTork is the new wireless dynamic torque transducer, distributed by Dalmar, ideal for calibration and control of torque, angle and pulse count of any type of pneumatic, electrical and electronic utensil up to 2,000 Nm. The main difference compared to traditional transducers is that with the ZippTork wireless transducer it is possible to verify the applied torque, that is the “force” which the joint receives, directly on your smartphone, tablet and/or pc, simply by installing the free software, compatible with both Android and Windows operating systems, on a device and configuring it with ZippTork. In this way it is no longer necessary to resort to expensive torque analyzers and deal with the natural obsolescence and maintenance to which they are subject.

In addition, it is designed to withstand shocks and tolerate tool vibration during assembly: equipped with a patented anti-vibration mechanism, the ZippTork transducer may be used on any type of pulse and continuous drive tool, both on the assembly line and in the laboratory, with a torque control accuracy of ±1%.

Flexible and adaptable

The ZippTork wireless transducer, not depending on the torque analyzer, is extremely flexible, versatile and easy to carry, making it easy to use on assembly lines to frequently check the calibration of electric and pneumatic screwdrivers. During assembly it is possible to monitor torque and/or angle in real time by displaying data and graphs on tablets, transmitted via a communication key called Dongle. Data thus stored in the software may be downloaded to Excel spreadsheets and/or transferred to peripheral devices or to the cloud server for further analysis and to ensure traceability. ZippTork may also be used after assembly both to analyze the joint, verifying the residual torque and collecting tightening data, and to check the static torque on torque wrenches. ZippTork, thanks to the memory capacity of the software, is able to store and retrieve information such as power status, signal quality, torque and angle. Units of measurement (lbf-in, kgf-cm, Nm) may be set according to the user’s needs and can be easily selected from the tablet. The five available ZippTork models (TTES, TTAS, TTEH, TTAH, TTEB) are sold in convenient kits together with the charging cable and ignition magnet and work with batteries, easily rechargeable via USB.