One platform for all applications

Aerotech Automation1’s version 1.2 offers numerous functional enhancements: at the heart of the new platform is the integrative portal control scheme. ETM modules and other new drive hardware can now also be seamlessly integrated into the processes.

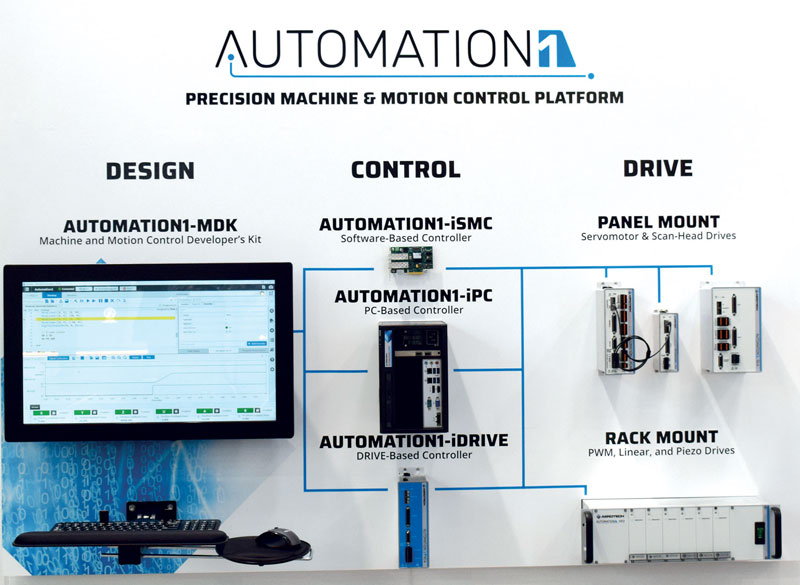

As a global builder of automation systems, Aerotech develops motion control and positioning systems and associated software solutions. These are used wherever high throughput with absolute precision is required. With the “Automation1 Precision Machine and Motion Control Platform”, the manufacturer developed solutions for the market for precision motion and machine control. With Release 1.2, the logical further development of the innovative control platform is now available. Automation1 operates as a complete machine control system with all components and thus offers much more than a mere “motion control”. The platform has its own software-based motion controller, which makes it easy to control different positioning systems as well as connected components. Areas of application include automation systems, precision laser processes, and test and inspection processes. With Release 1.2, Aerotech were able to implement some important technological innovations that make the platform as a whole even more integrated and powerful.

Flexible integration of ETM modules

Thus, Automation1 now has a new portal control scheme, commonly referred to as R-Theta or Portalgier control. This will serve as the basis for all further portal control schemes in the future. The solution also now supports the Enhanced Throughput Module (ETM). By directly measuring the unwanted movement of the machine base and feeding it back to the controller, the positioning performance of highly dynamic motion systems is improved. The seamless interaction of the Dynamic Controls Toolbox with the Aerotech controllers allows the servo system to perfectly execute the desired motion path. ETM modules can be precisely aligned via the Configure workspace in Automation1 Studio. By measuring and accounting for unwanted machine base motions, the ETM automatically improves positioning performance in collaboration with Automation1.

Advanced integrative C-API-based control capabilities

A new interface for programming Windows desktop applications in C or C ++ has been added to the controller itself with C-API (Coherent Accelerator Processor Interface). Also, Automation1 Studio’s Machine Setup Configuration Wizard now supports new XC6e, SI4 and XL4s drive hardware.

The high-end servo motor hardware is an essential part of the Aerotech motion control platform. Not only do the drives meet all the requirements for best-in-class motion control performance, they also provide tools to manage and control precision motion control applications. Aerotech’s drives include ample memory for process control and data acquisition, extensive I/O points for sensor integration and operator stations, and interfaces to standard industrial laser tools. In addition to functions such as Position Synchronised Output and Infinite Field of View, Release 1.2 now also includes autofocus, which will enable machines to be controlled even more precisely in the future.