Turla Becomes TEXP RFK

The Italian fund Red Fish Kapital has taken control of the industrial activities of Turla, the historic manufacturer of aluminium extrusion plants. An important step towards the future of extrusion plant production

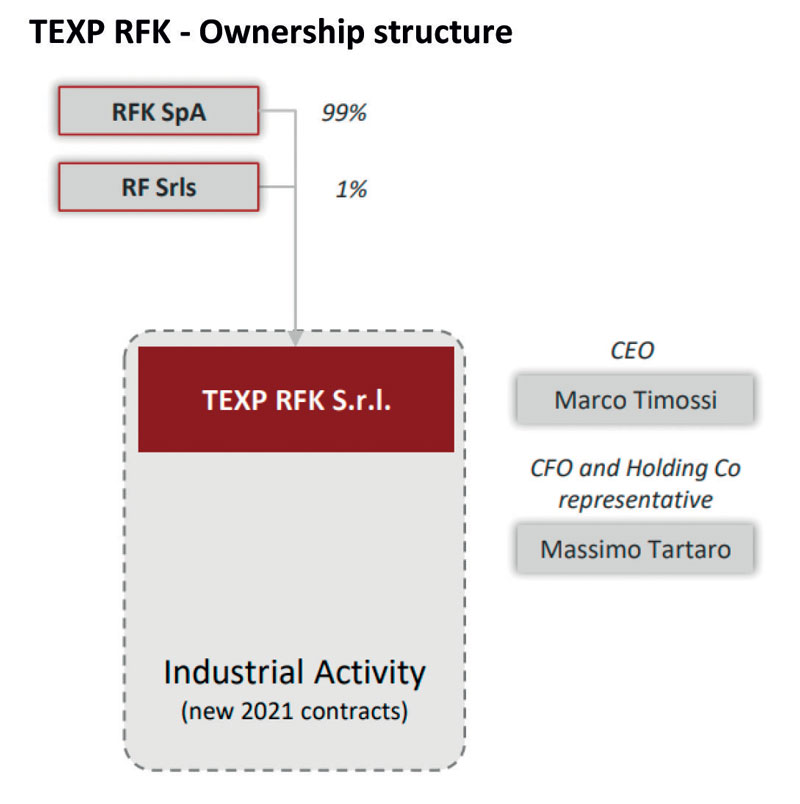

Between 2020 and 2021, an important change took place in the corporate structure of the historic Brescia-based company Turla. In the first step in 2020, the company Turla Srl separated production from real estate assets. This includes the new factory of about 20,000 square metres built in 2019. The industrial activity took on the new name Turla Extrusion Plants (TEXP Srl) in November 2020. In the second step, which took place in May this year, the Italian fund Red Fish Kapital SpA took control by leasing the TEXP business, thereby creating the new company TEXP RFK Srl. Founded in 1967 by Franco Turla in Valtrompia, near Brescia, over the years Turla Srl has become a reference point in the design and construction of complete aluminium extrusion plants. Since the early 1980s Turla has been one of the main suppliers of important international groups specialising in the production of aluminium extrusions, such as Constellium, Grupa Kęty, Hydro, to name but a few. In 2008, the company also started producing aluminium extrusion presses, so as to be able to offer its customers the complete turnkey system, from the extrusion press and auxiliary machines to cooling systems, basket handling systems, and ageing furnaces. In the following years the company completed its offer with an efficient after-sales service, using the best of the technologies developed in over fifty years of history to help improve productivity and reduce downtime, working with its customers all over the world to find and propose new solutions to meet the market’s requirements. The Red Fish Kapital fund is making major changes to TEXP’s structure, and today we talked about this with Luca Lorini, TEXP’s Commercial Director, and Vincenzo Caccioppoli, Marketing and Communications Manager.

How does TEXP fit into the industrial strategies of the Red Fish Kapital fund?

The RFK fund is an investment structure capable of maximising the opportunities for long-term industrial value creation in SMEs. It has accrued extensive experience in various industrial sectors in Italy, including aluminium, a business with definitely interesting future prospects. The reorganisation of Turla was essential to meet the growing demand for plants and to reach new markets. With the aim of creating a stronger company, improving both management and financial aspects and reliability towards customers, the industrial holding Red Fish Kapital decided to create the new company called Turla Extrusion Plants RFK. TEXP RFK took over all the orders and projects already belonging to the Turla group and, during the last few months, completed the handover in order to start the activity in the new company in full swing.

You mentioned important requests and new orders for presses. From which countries do these requests come?

Requests come in from all over the world, both from European and non-European countries. We have always been oriented towards international markets in general, from which we are receiving requests for extrusion lines of all sizes. The amount of orders and new requests is one of the reasons behind the company’s reorganisation. From the beginning of 2020 until today, despite the period of the sadly notorious pandemic, we have nevertheless concluded several contracts for the construction of new plants. We are talking about new complete lines as well as various revamping orders; Russia and Belarus are markets which have opened their doors to TEXP RFK, as well as Belgium, Australia, Spain and Germany have confirmed their trust in TEXP RFK with new orders with deliveries expected both in 2021 but especially in 2022 and 2023. This strong demand shows the great vitality of the aluminium extrusion equipment market and after the slowdown in the first months of 2020 we are witnessing a real surge in requests. In fact, we expect to significantly increase our already large order portfolio this year, with additional orders on which we are currently working. Turnover at the end of 2021 should therefore show major improvements.

Let us now talk about the reorganisation and development of the company…

TEXP RFK’s project foresees new recruitment, both of experienced personnel in the sector and of Junior profiles to guarantee the growth and development of the company’s resources and thereby increase the construction and design capacity of our plants, always aiming at the cutting edge of applied technologies. Today, two drivers of change, one dictated by digital technology and the other by the virus, are intertwined and mutually reinforcing. It is no coincidence that the companies which came through the health crisis most successfully are the most digitally advanced. But it is not just about technology. Even before leading to the adoption of digital technologies, the imperative of change concerns the cultural dimension. In this sense, every organisation needs to transform the mindset of managers and employees, guiding them to embrace innovation without reservation. For this reason, the implementation of change management processes is becoming a strategically valuable option. Change management interventions must aim at changing the corporate culture by appealing to shared values, relying on people to help spread the change, and creating an environment consistently supportive of transformation: an environment in which every message received from employees flows into clarifying the reasons for the change and what everyone has to do to make it happen. Organisations must move from a logic of emergency/survival to one of long-term success and accountability. A new Business Unit dedicated to technical support and customer care is also being created within the company, where a specialized team of technicians will be dedicated full-time to providing services and guaranteeing performance and results for our customers. Aware of the importance of after-sales service TEXP RFK has launched this new project purposely to better assist and serve its customers and thereby continue its growth.

In brief, what are the main qualities which characterise your offer compared to your competitors?

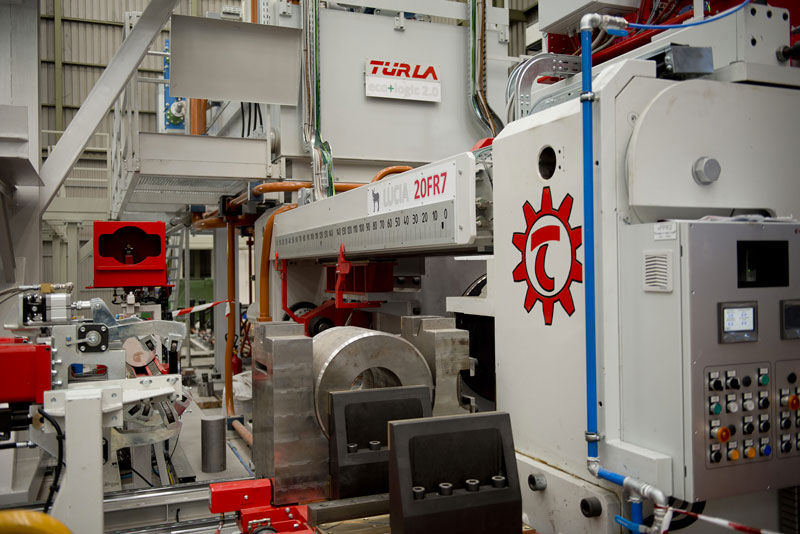

First and foremost, our desire and ability to produce tailor-made systems, designed to fully satisfy the requests and needs of our customers, as opposed to those in our sector who are only able to offer a standardised product. We believe that plant customisation has become an increasingly important and fundamental requirement for each of our customers, whatever products they produce and market, because this represents added value for them in their production process. Another distinctive feature of TEXP RFK is that in recent years we have developed very effective energy saving concepts and applied them to every single machine we supply: the environmental and economic impact is now very important in the evaluation of any new investment. Some examples of the results obtained are the reduction in gas consumption in the billet heating furnaces, the reduction in the emission of fumes into the environment, the new hydraulic design of the presses which involves the use of innovative components making it possible to reduce energy consumption and increase performance. Our press has been developed with the ECO+LOGIC 2.0 hydraulic system, which in recent years has received very positive feedback from all customers who have started using it. We guarantee our customers an energy consumption of less than 100 kWh per tonne of aluminium produced. Significant evidence of this can be seen in the latest 5,000-ton presses installed in Spain, where we have shown significant energy savings even considering the enormous masses and powers which these machines require. But the best publicity definitely comes from those of our customers who, after purchasing the first press equipped with ECO+LOGIC 2.0, have confirmed its quality and performance by ordering a new press and specifically requesting the same hydraulic system installed. Another qualifying point for us is the research aimed at reducing the noise of our systems. This is to improve the working environment for all production operators. I would like to conclude with the attention to detail and the choice and use of state-of-the-art components, to always guarantee the maximum performance and durability of our plants and every single auxiliary machine they are made of. In a market also characterised by supply from non-European countries, it is essential to offer quality, continuous assistance and above all improved productivity to make our customers leaders in their markets. Within just a few years, an investment in one of our plants will rapidly be recouped, compared to less performing low cost standard products.

Regarding process control software, for instance for controlling extrusion temperatures or productivity, have you developed any particular solution?

To answer in detail, for performance control during the production cycle we used new types of pyrometers which monitor the temperatures of the billet at the exit of the furnace, or of the profiles at the exit of the press before and after the cooling tunnel, and which interface with our software system for data management, acquisition and supervision, software which we develop entirely in-house with a dedicated team. Besides, in collaboration with a specialised company in Brescia, we are developing control systems with thermal scanners to monitor the temperatures and mechanical surface characteristics of extrusions during production. Control using scanners makes it possible to instantly check how the profile is being formed during extrusion, with an immediate dimensional analysis. This makes it possible to understand whether or not the product is within the required allowances in a short time, reducing the rejection of non-conforming products. This is a brand new pioneering project in our industry which we shall start testing as from the end of this year.

Regarding the other machinery in the plant, such as stretchers, extrusion benches, packaging systems, do you have any updates or news?

On all the components of the extrusion plant we are replacing the hydraulic power and control part with electrical technology allowing us to optimise control, increase performance and reduce environmental impact and consumption, while the parts which still require hydraulic devices are developed following the ECO+LOGIC 2.0 system philosophy. One example is our presses where we guarantee zero energy consumption during waiting times, since with the ECO+LOGIC 2.0 system the pumps only use energy when necessary. As far as our pullers are concerned, in recent years we have developed a profile handling system on board the press completely built with electric motors, where also the system of movement of the profiles along the sliding beams has been simplified and perfected to guarantee maximum performance and long life of the components. New basket handling systems as well as handling of large profiles have been produced in recent years with a special focus on developing markets. In other cases, we have developed solutions for special handling and operations for profiles with very short lengths, for example where the line is designed to allow fast and precise cutting of products required by markets such as automotive, with considerable cost savings during subsequent machining.

As regards software, we now offer globally our ADAM system, which allows the tracking of the entire product cycle and all its production stages, starting from the billet casting number and recording and managing all the profile parameters during the process. ADAM is a sophisticated supervision software interfaced with our plant software, which continuously tracks the various stages of production, organising all the production processes in constant communication with the customer’s ERP from which it receives every input and with which it interacts for detailed control of each individual process. Last but not least, a brand new software which we are currently testing with some customers and which will allow immediate remote assistance from our specialised technicians. The new software uses special communication devices such as applications on the phone and augmented reality ‘glasses’ allowing remote intervention by our technical support. In practice, the operator will be guided through his work and will be able to have direct access to maintenance manuals or videos demonstrating the detail observed or the operation required. This is to guarantee a fundamental after-sales service in ultra-fast times and competent technicians always available to our customers. We are taking a further step towards ensuring a complete, efficient and uncertainty-free supply for all our customers.

In consideration of what we have said, what are your expectations for TEXP RFK, given that the aluminium market is very dynamic but is starting to suffer from difficult conditions caused by the increase in raw material prices?

Since the beginning of February 2020, the world has been thrown into a new reality. The sudden and widespread propagation of the Covid-19 virus has taken most Western and Eastern societies by surprise, causing disruptive effects on the economic and social fabric, pushing every company to face a series of new challenges. While on one hand the contingency accelerated processes of change already underway in the world of work and caused some established beliefs to be challenged, on the other hand the unbridled change appeared, in some cases, ‘temporary and precarious’, pending a return to pre-pandemic ‘normality’. But a return to previous models is not realistic: it is necessary to frame the actions which companies will take in the coming months as part of a long-term process which will not lead to a ‘new normal’, but to an alternation of ‘next normal’ in order to adapt quickly. In this respect, TEXP RFK’s future prospects can only be the best, considering that the company’s reorganisation is taking place during this period, when the market is very dynamic and growing but where at the same time we face the rising prices of raw materials and the struggle for their procurement. Therefore, the outlook sees TEXP RFK as a company which will be able to adapt to the continuous market fluctuations thanks to its ability to offer products adapted to demand and proving to be a company always able to find the right balance between product quality, production and profitability.