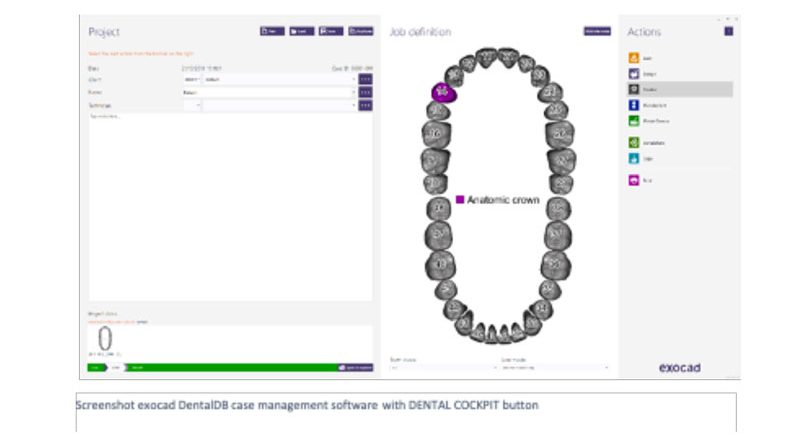

Un sistema di saldatura laser per la produzione di dispositivi medici

Coherent introduce il sistema di saldatura laser ExactWeld 410 per la produzione di dispositivi medici. Utilizza il software Laser Framework che semplifica la convalida del processo e aumenta l’efficienza della produzione grazie alla sua interfaccia intuitiva con la visione artificiale e le funzioni di monitoraggio del processo.

Leggi il seguito